Tower Bridge in London

Introduction

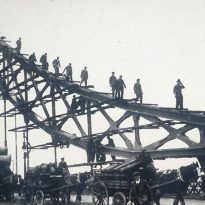

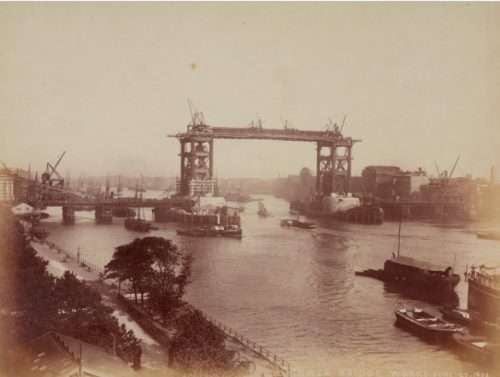

The Tower Bridge is a bridge that combines two systems, swingarm and suspension, built between 1886 and 1894. The bridge crosses the River Thames near the Tower of London and has become an iconic symbol of the city. Its construction took eight years, five main contractors and the tireless work of 432 construction workers every day.

History

After contemplating the need for a new bridge that linked the opposite banks of the Thames, because before the increase in traffic and population the existing ones did not cover the needs, a committee was appointed to consider the matter and inform about the different plans that had been proposed. These included schemes for low-level bridges with oscillating openings of various types, and high-level bridges with inclined approaches or with elevations at each end. It was also proposed to build a railway line at the bottom of the river and carry out an itinerant staging with its deck protruding above sea level or proposals were considered for a subway and for large paddle wheel ferries. None of these schemes were approved.

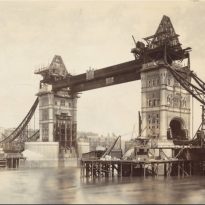

In 1878, Horace Jones, the architect of the city, presented a proposal for a bridge at a low level on the tilting principle, that is, a bridge at level with the streets, with two leaves or arms that could be raised to let the ships pass downstream and be lowered to allow vehicles to pass from one side to another through the canal. In 1885 a Law of Parliament was passed that empowered the City of London Corporation to build the bridge. Horace Jones was named architect and received the title of gentleman, but he died the same year passing responsibility for its construction to engineer John Wolfe Barry.

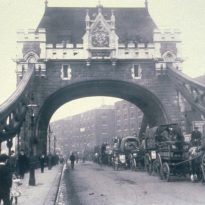

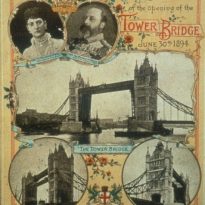

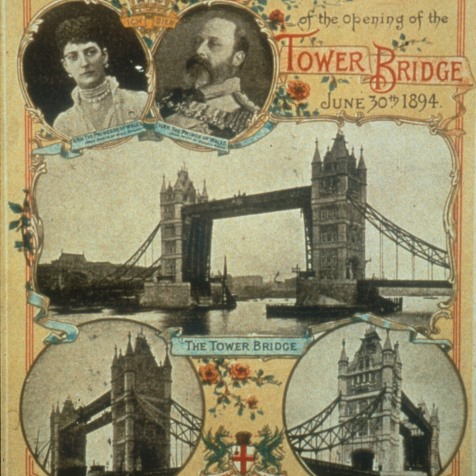

The first stone was laid in April 1886. The bridge should have been completed in 1889, but difficulties arose and Parliament was asked twice to extend the time to complete the work. He did, and the bridge finally opened on June 30, 1894, having cost approximately £ 1,000,000.

Location

The mobile bridge extends along the River Thames joining the municipalities of Tower Hamlets and Southwark. It is a distinctive landmark that aesthetically complements the nearby Tower of London, England.

The borough of Tower Hamlets (London Borough of Tower Hamlets), in the United Kingdom, is located east of the City of London and north of the River Thames, covering a large area of the traditional East End and a part of the remodeled Docklands . While the London Borough of Southwark is located in the south of London, forming part of Inner London and connecting with the city of London by bridges.

Concept

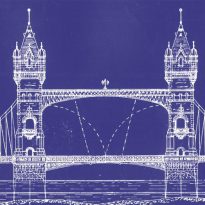

The Tower Bridge in London is one of the most recognizable bridges in the world. His Victorian Gothic style derives from a law that forced designers to create a structure that was in harmony with the nearby Tower of London.

John Wolfe Barry designed, together with Horace Jones, a swing bridge with two towers on docks. The central section was divided into two equal arms or leaves, which could be raised to allow the flow of river traffic and for the two lateral sections, suspension bridges were used.

Spaces

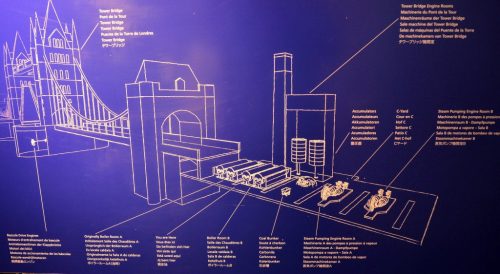

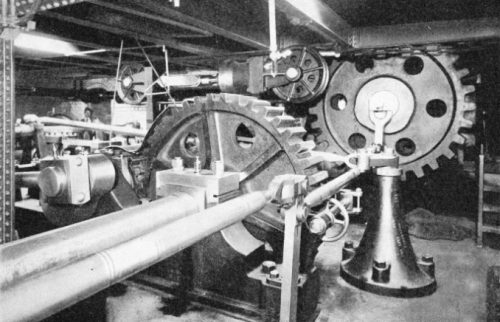

The proximity of the port and its location in the direction of the sea required the bridge to allow large vessels to pass through. Hence the decision to create a drawbridge that can be opened to accommodate boat traffic. The mechanism to open the bridge is hidden in the two towers. Until 1976, when the mechanism was electrified, steam energy was used to pump water to the hydraulic accumulators that operated the engines. This old system is still in good condition and is used as a tourist attraction, although today platforms rarely rise. One of the chimneys of the old system, which is often confused with a lamppost, connects to an old fireplace in a guard room of the Tower of London.

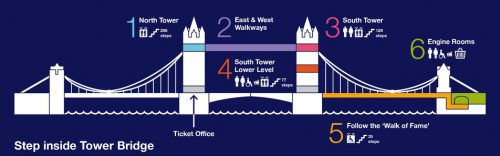

The main deck of the bridge supports two traffic lanes with a width of 10.67m, which pass between two pedestrian walkways of 3.81m, the suspension sections and in the swinging opening section of the bridge, with the walkways separated from the road by fences. Car lanes pass through each of the two towers, while pedestrian walkways pass around.

Each platform is more than 30 meters wide and can be opened at an angle of up to 86º. When it opens, the bridge has a light of almost 45 meters. Years ago it used to open almost fifty times a day, but today it only rises a thousand times a year. The walkways were originally designed to allow pedestrians to cross even when the bridge is built, but they became a gathering place for prostitutes and thieves, so they closed from 1909 to 1982.

Bridge elevators are preprogrammed for the cruise pass and visitors can check the bridge’s website to know when it will go up or down.

Inside the bridge is the Tower Bridge Exhibition, an exhibition area that encompasses the walkway and the two towers where you can see the Victorian engine room.

Renewal

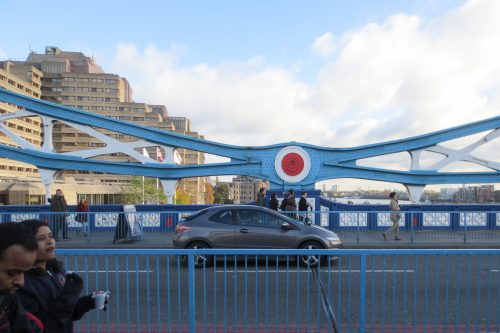

In 2014, glass floors were installed on the walkways, giving visitors an unusual view from the bridge. The 11-meter-long glass floors are more than 40 meters above the river, allowing traffic from the bridge or the opening and closing to be observed from above.

Structure

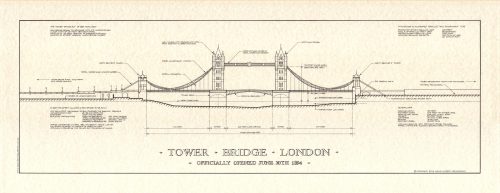

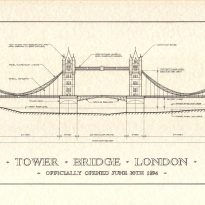

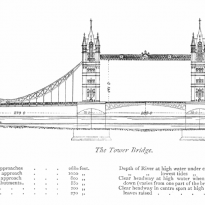

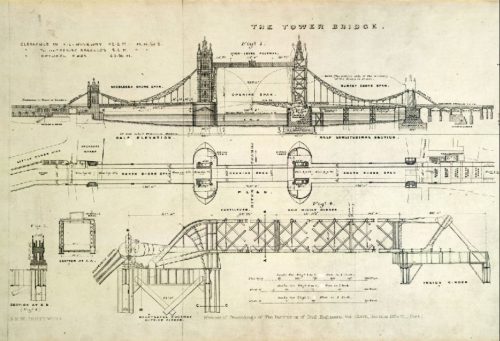

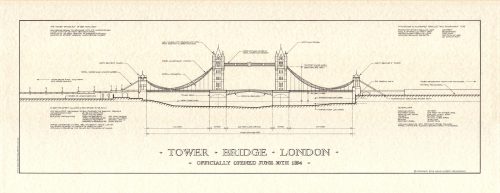

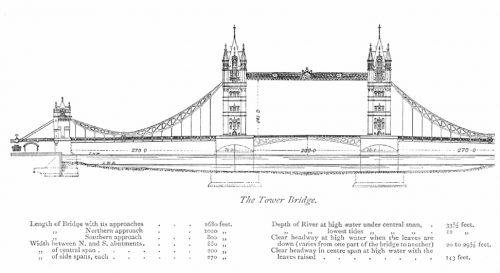

The structure of the Tower Bridge is made of steel covered with masonry and stone. The bridge has a length of 244 m with two towers 65 m high, built on docks, combining two bridge systems, swingarm and suspension. A swing bridge is a kind of drawbridge that works on a pivot and is balanced with a heavy weight.

The bridge was completed in 1894 and provides an opening 76 meters wide. Its twin towers rise 64.92 meters above the Thames. The length of the bridge between the two buttresses is 268.22m divided into three sections. The two lateral spans are suspension bridges, each 82,30m long, with the suspension bars anchored both in the buttresses and through the bars that are inside the bridge’s upper walkways. The pedestrian walkways are 44m above the river at high tide. The thick chains that have these sections, touch earth at their ends, on support towers of moderate height anchored on the shore and connecting to the tall twin towers. Heavy tie rods, at the level of the connecting beams, join the two pairs of chains so that in the center one acts as an anchor for the other.

The central opening that opens between the towers is divided into two equal tilting blades, which can be raised at an angle of 85º to allow river traffic to pass. The rockers, which weigh more than 1,000 tons each, are balanced to minimize the required force and allow opening in five minutes.

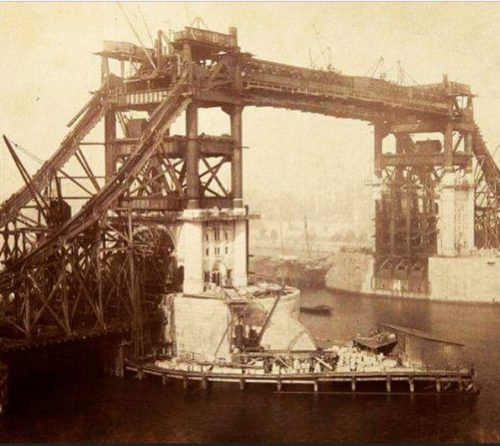

Tower Bridge docks are much more complicated structures than the pillars of an ordinary bridge. In addition to supporting the towers that support the upper beams for the high level sidewalks and the suspension chains of the fixed sections, they also house the counterweight and the machinery that operates the scales.

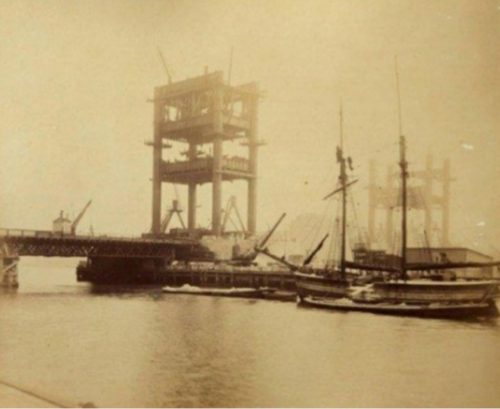

Docks Construction

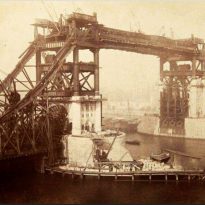

Its construction had to be done separately, because if they had been done at the same time the staging would have taken up too much space of the river and obstructed its intense traffic. For that same reason the builders had to adopt a system of small drawers to cover the area where the foundations of each of the docks would be built.

The drawers used to secure the base of the docks consisted of wrought iron safes, with no top or bottom and a rectangular measure of 10.36x 37.95m. To ensure a good base, it was considered necessary to sink them to a depth of approximately 6.40m in the riverbed. Twelve drawers were used for each dock, with a space between them of 0.76cm. On the north and south sides of each pier there was a row of four drawers, each of 2.60m2, joined at both ends by a pair of triangular drawers, formed approximately in the shape of the finished pier.

The method adopted to build and sink the drawers was unusual. First the drawers were built on wooden supports at the site where it would sink. The drawer had a height of 5.79m and was divided horizontally into two sections. The lower portion was known as the permanent and upper drawer, which could be removed when the boardwalk was completed, it was called a temporary drawer. The objective of this upper portion was simply to keep the interior free of water while the dock was built. When it was finished, the supports were removed and the permanent drawer was lowered to the river bed by four powerful screws attached to four drop rods. After the drawer had reached the ground, several lengths of temporary drawer were added to the permanent section, until the top of the temporary portion appeared above the water level. The union between permanent and temporary drawers was adjusted with Indian rubber.

Materials

Plans for its construction began around 1876 when East London became a very densely populated area and a bridge over the Thames in that area of the city seemed a necessity. It would take another eight years and many discussions about the design before construction began.

The steel structure of the bridge is clad in a masonry that harmonizes with the architectural character of the adjacent Tower of London, Cornish granite and Portland stone on a brick base.

In its construction 6,654.46m3 of Cornish and Portland stone granite, 20,000tn of cement, 53,519m3 of concrete, 31,000,000 bricks and 14,000tn of iron and steel were used. The cost of the docks was £ 111,122.

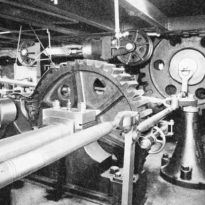

Hydraulic accumulators

The swingarms on the bridge were operated by hydraulic systems that used steam to power the huge pumping motors. The energy created was stored in six massive accumulators and was available when needed to lift the bridge. The batteries fed the engines that drove the swingarms up and down. Despite the complexity of the system, the scales only took about a minute to rise to their maximum angle of 86º

Video