Sears Tower – Willis Tower

Introduction

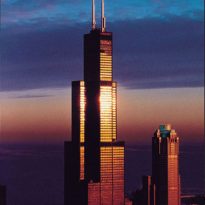

In 1969 Sears, Roebuck & Company was the largest retailer in the world with approximately 350,000 employees. Its executives decided to join the majority of the thousands of employees in offices located in every area of Chicago in one building on the western edge of the city. With immediate space demands of 279,000m², and with predictions and plans for future growth that will require even more space the architects of Skidmore knew that the project would generate one of the largest office buildings in the world.

Commissioned by Sears, Roebuck & Company, it was designed by the chief architect Bruce Graham and structural engineers Srinivasa and Fazlur Khan of Skidmore, Owings & Merrill, SOM.

Construction began in August 1970 and the building reached the maximum height expected on May 3, 1973. From that date until 1995 the tower was the headquarters of Sears Roebuck & Co., when the trader moved to the suburbs Chicago. The building design, flexible and iconic plant height allowed him to become a reference point for a number of companies and firms of Chicago. Today, the tower is well maintained and remains a center of activity on the Chicago circuit.

- Willis Tower

In 2009 the company Willis Group Holdings Ltd. bought the building and naming rights were part of the negotiations, to be renamed Willis Tower. This change was not well received by the people of Chicago that is still referring to the building as the Sears Tower.

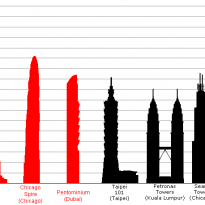

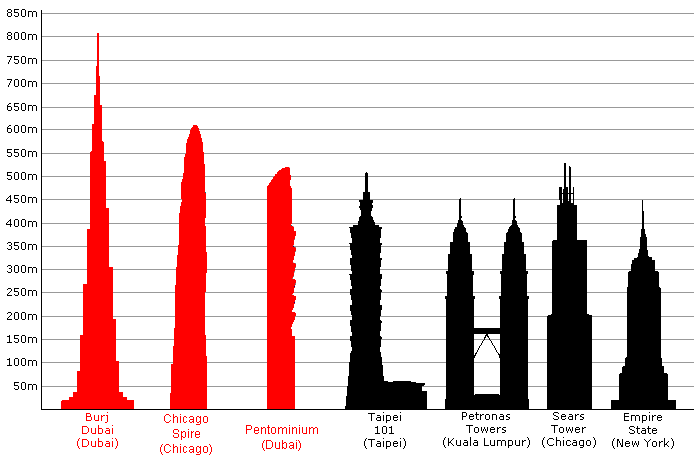

Design

The first designs were for a boxlike structure exclusively for Sears, but architects and real estate advisers lobbied to lift a taller tower with leasable upper floors. With 110 plants and 443m tall structure proposal it exceeded the World Trade Center for approximately 30m. According to company officials the building would be “as high as the FAA, Federal Aviation Administration, would allow them”. For nearly 25 years, the Tower held the record of being the tallest building in the world until the Towers Petronas to Kuala Lumpur, Malaysia, were built in 1998.

Location

The Tower is strategically located in the business district of Chicago, Illinois, United States, on 233 South Wacker Drive, in the heart of the West Coast, the first sub-market town, home of his coorporations largest and railway stations used by people living outside the city.

Its construction occupies the entire block, 12.140.57m², Francklin Street bounded by Wacker Drive, Adams Street and Jackson Boulevard.

Concept

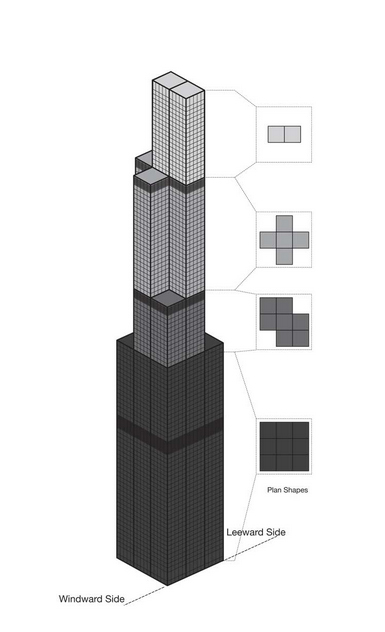

One of the very important aspects to consider when a skyscraper is done is that the higher the greater height is the effect of the wind on its structure. To counteract this effect at lower buildings it is common to stiffen the structure with a bracing X to prevent deformation or displacement thereof in some cases by the outside or with walls of reinforcement around the vertical communication cores. This process in a steel structure high-rise would be extremely expensive, in the case of the Sears Tower.

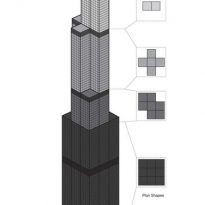

It was necessary to develop new structural concepts, not just costs, but also because the client did not want a reinforcement X on the front of his building. The original engineer of Bangladesh, Fazlur Rahman Khan was asked to respond to these needs by creating a new structural concept known as “screen tubes” concept became the basis for the construction of tall buildings today and earned He is considered the “father of the tubular designs” in skyscrapers. For these Sears Tower “tubes” midsize create a structure that appears to the eye created by a series of individual towers joined ending at different heights and provide free plants in columns ranging from 3,800 to 1,100m2, with a maximum wind drift, on top of the building, just 0.30cm.

Spaces

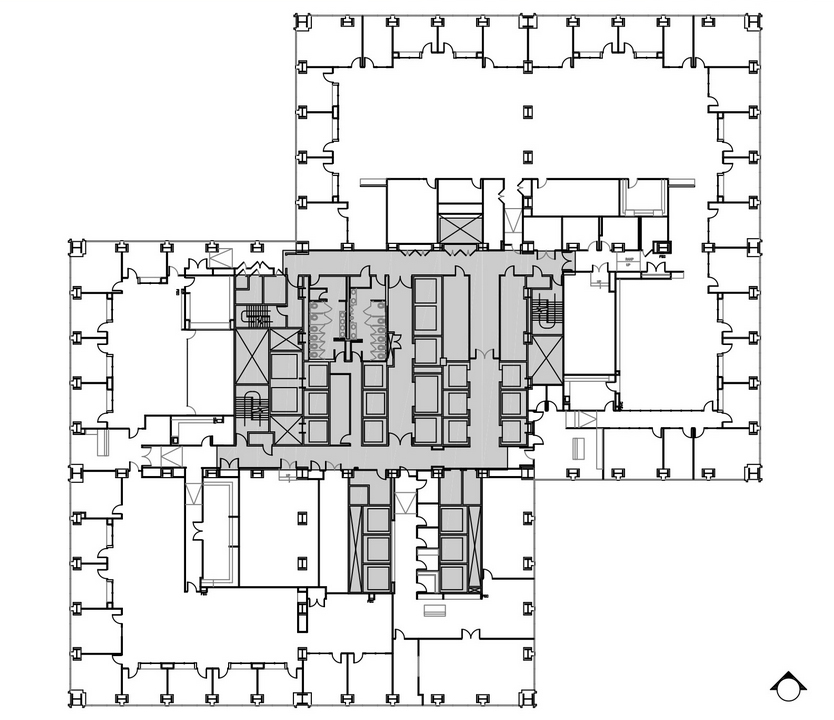

Sears Tower is an attractive and modern office with a floor area of 418.64 square meters of which are rentable 353 961 m². The surface is divided into 110 apartments, 108 above ground, which is accessed with 104 elevators, 16 of which are double height. It was the first skyscraper in the world to incorporate this type of lifts.

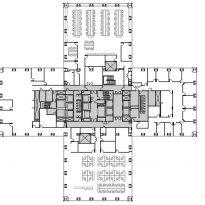

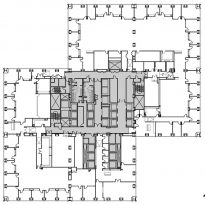

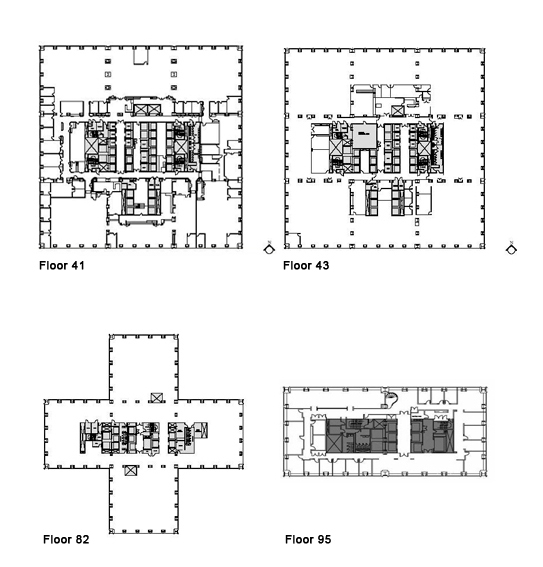

Reverse iconic design of the structure was conceived as a direct result of the space requirements of the client. designers to develop a building that incorporated not only very large plants for offices, necessary for the operations of the company, but also a variety of smaller plants for tenants that required less area were asked.

It is vertically divided into three zones of between 30 and 40 floors, each of which has a double-height lobby, as well as having three mechanical floors.

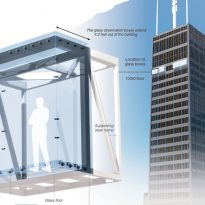

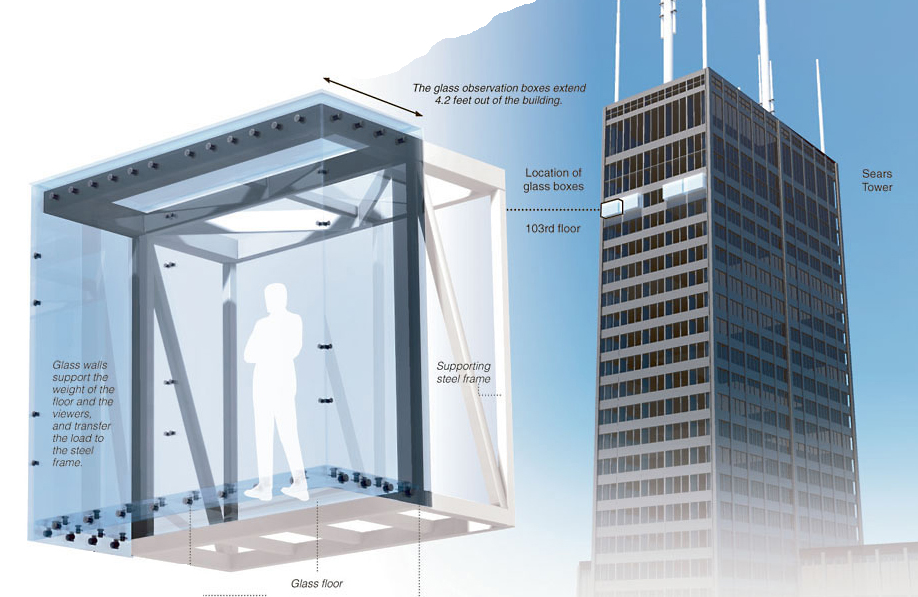

- Skydeck Pavilion

In front of the tower there is a separate entrance for tourists wishing to enter the Skydeck Pavilion, agregrado by Skidmore Owings & Merrill in 1985. 412.69m high, in 103 floor is a viewing platform which on clear days allows see four states, Illinois, Indiana, Wisconsin and Michigan. This platform is readily incorporated as an innovative addition that is in the spirit of the original design. Minimum glass balconies allow five sided views in all directions and provide an experience that approximates feel suspended in the air. The projections are approximately 1.22m deep, 3m high and 3m wide. They are made of laminated glass panels 3.81cm thick hanging from a steel frame that rides on rails, allowing it to be retracted into the building for cleaning and maintenance.

Other services include a platform for the dissemination of world-class conference center and health facility, all with exceptional technology features.

Structure

It is the tallest building in the world with all-steel structure, columns]] and beams in a system “of megamódulo”.

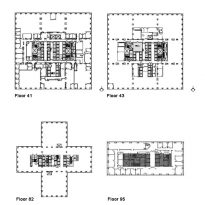

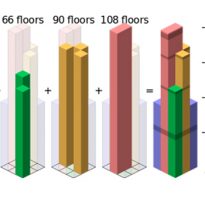

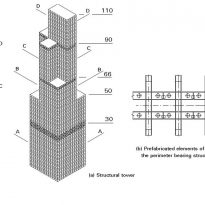

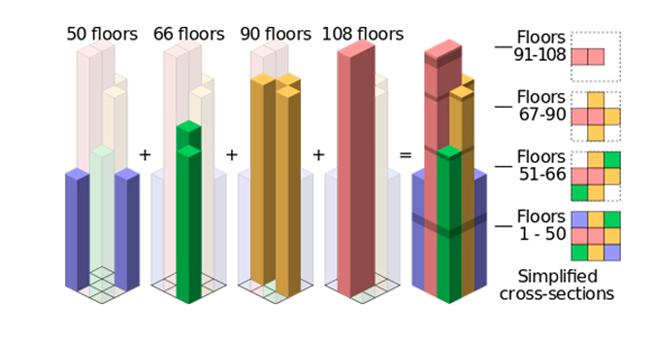

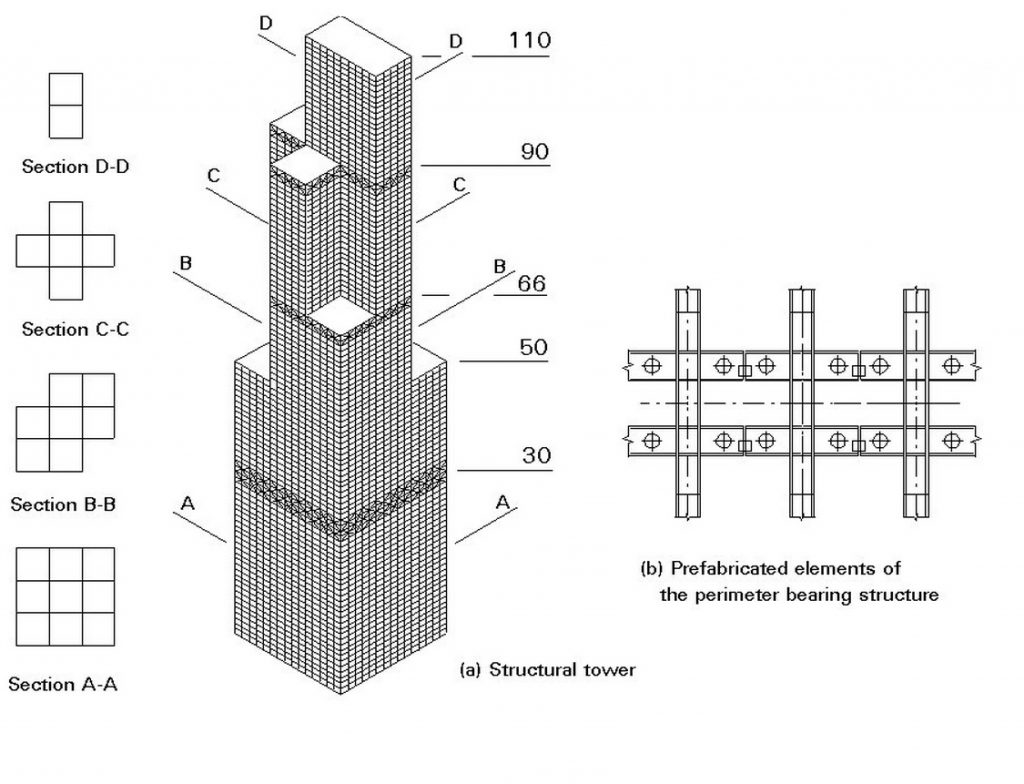

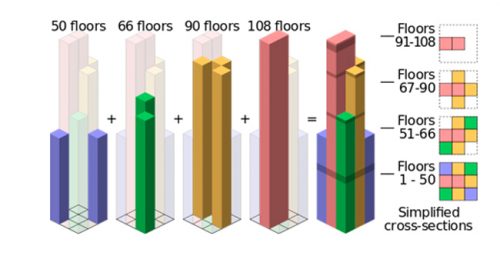

The tower structure is solved with nine square modules, each rigid within itself without internal supports. The floors are suspended from the tubes, a technological innovation of the engineer Fazlur Kahn, based on the theory that a building built on a series of tubes would be lighter and stronger than a building built to a traditional steel skeleton. At the base of the building 9 modules form a square, of 22.86×22.86m, grouped as a closed square and arrive intact through the first 50 floors, finishing at different heights and creating a form with multiple levels. From this level the number of modules / tubes is decreasing until it became only two steel tubes from the 90th floor to the top.

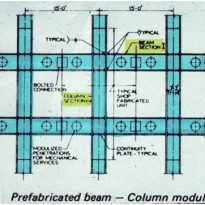

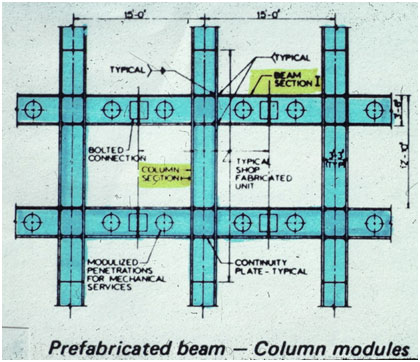

The structural modules are inserted into reinforced concrete caissons reaching bedrock and are also joined by a concrete mat. The structural steel frame was pre-assembled in sections and then bolted in place. Each module 7.6×4.6m was prefabricated and then to be taken to place large trucks and once placed in place by cranes, join connections.

Skin, lightweight, black aluminum and bronze tinted glass reduces reflections and serves as insulation between the inner and outer structure in order to maintain a relatively constant temperature, which minimizes the expansion and contraction of the frame.

Materials

The mega structure was made with structural steel. 7.6×4.6m each prefabricated module is formed by a steel column with a height of two floors and a girder welded on each side in the middle. These beams are those that were screwed together, once set in place. The tubes were reinforced trusses wrap covering two floors, around levels 29-31, 64-66 and 88-90.

Each floor slabs are of reinforced concrete and are supported on rolling 1m depth trusses bolted to the columns.

The Sears Tower has a black anodized aluminum exterior with tinted glass in bronze black lines vertically tours that highlight the tubes. The large windows offer a maximum use of natural light and views, reinforced by the decline of the modules created on all sides of the tower.

Inside the building were placed 40.23Km pipes, electrical wiring 2.440Km, 128.75Km steel cables for elevators and 145,000 luminaires.

In the common areas of the building quality materials that enhance the prestige of the building, in the travertine plates coated with stainless steel together, polished granite floors and decorative lighting on the ceiling lobby walls were used.

Six robot to wash the 16,100 windows of the Sears Tower machines were mounted on the roof.