Laminata House

Introduction

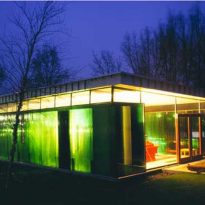

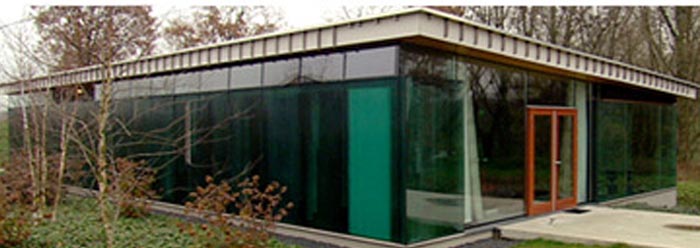

Laminate the house in Leerdam, Netherlands, home of the Dutch glass industry, was scheduled as a glass house designed by artist and Kruunenberg Van der Erve Architecten (Kruunenberg Gerard Van der Erve and Paul) for the Housing Association Leerdam ( GWL Koopwoningen).

These architects Dutch non-star system architecture, designed this unique project. This differs from the Glass House Philipp Jonhnson basically all that is made of glass, including its structure and offering an interesting transparency, through the translucent veil of green walls.

Situation

Built in a residential neighborhood Leerdam, city and municipality located west of Holland (Netherlands) and known since the eighteenth century for its glass industry and timber.

Spaces

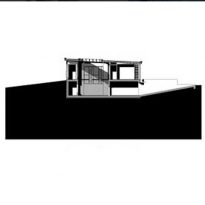

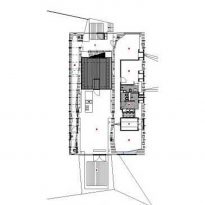

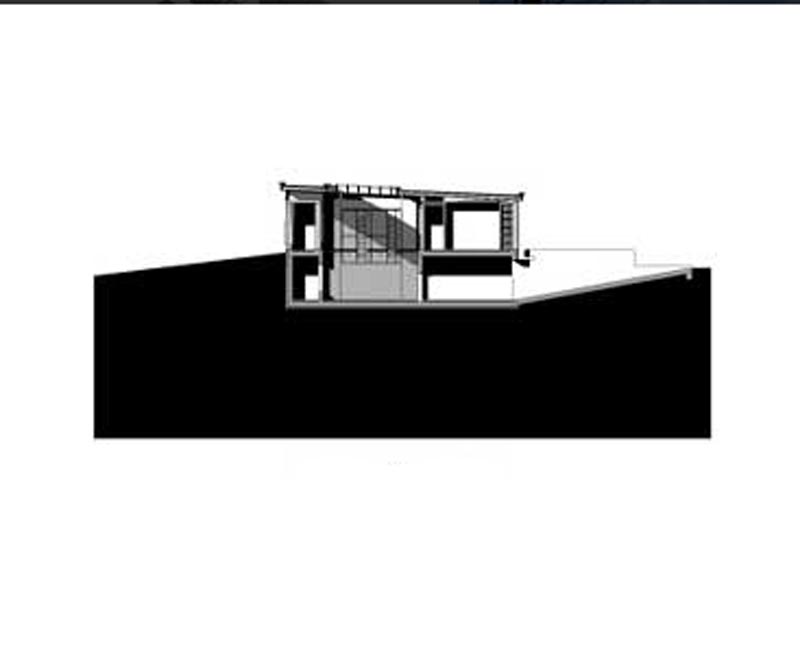

In a basement floor and the flat-roofed house (single-story) is heading lengthwise into two sections in the intersection of which are located the public housing:

1. The largest section accommodates the main part of the house with two bedrooms, shared bathroom and study.

2. The smaller section accommodates a bathroom and a foyer.

3. Between the two wings there is a living-dining room with terrace which is adjacent to a large patio window and double-height entry that descends to a basement with a garage and an area of study.

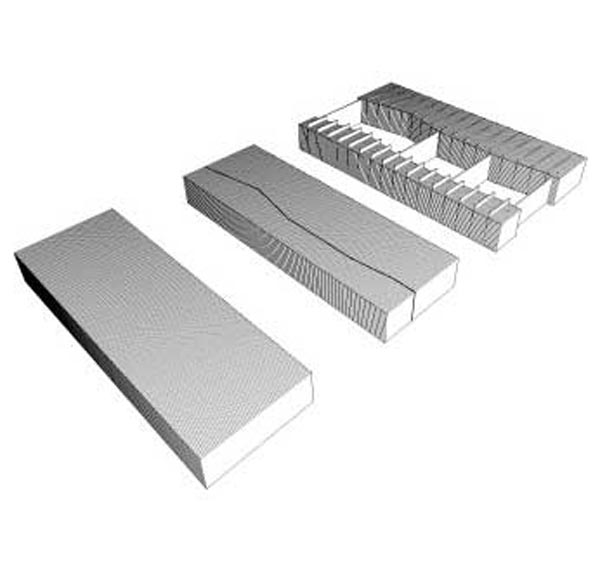

Structure

The building sits on a concrete slab and the structure is organized on the basis of laminated glass, which distributes the loads.

The materials used in the union of the different layers of glass preserves a certain amount of structural movement between each sheet of glass to provide flexibility in the set.

Materials

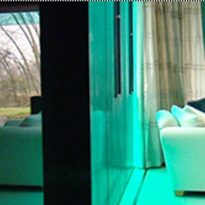

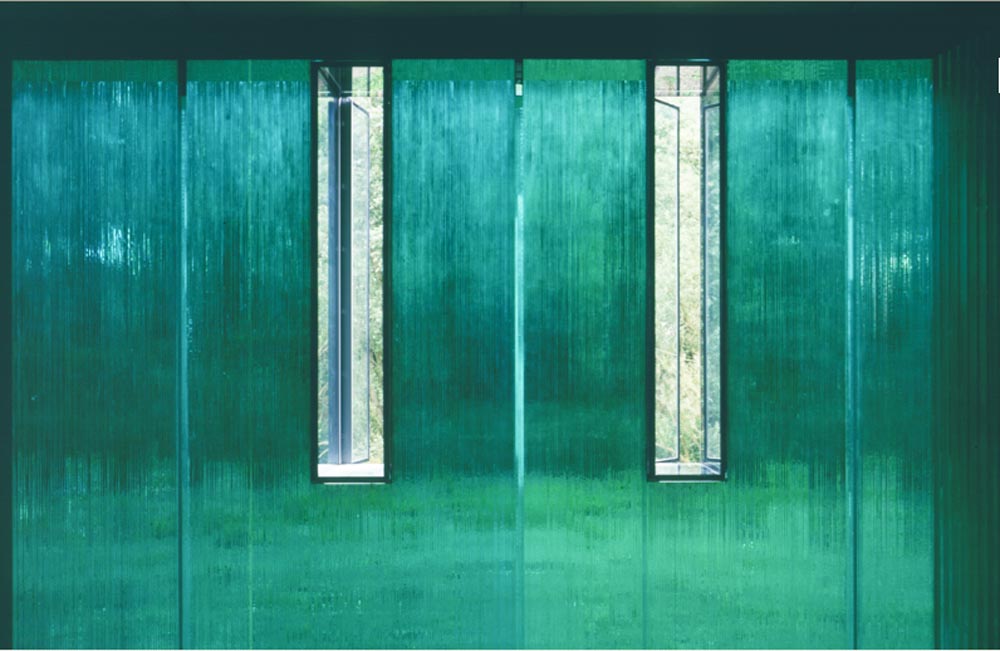

Laminate the house uses for its glass facades to the main internal walls, but not as the typical flat sheet or double glazed units. In fact, the walls and the entire structure is composed of pure glass.

It is a bold experiment that uses sheets of glass structure, while at the same time meets the requirements of privacy and security of the inhabitants.

The glass walls

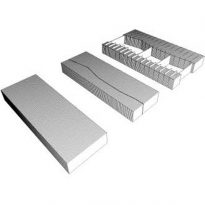

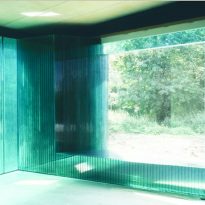

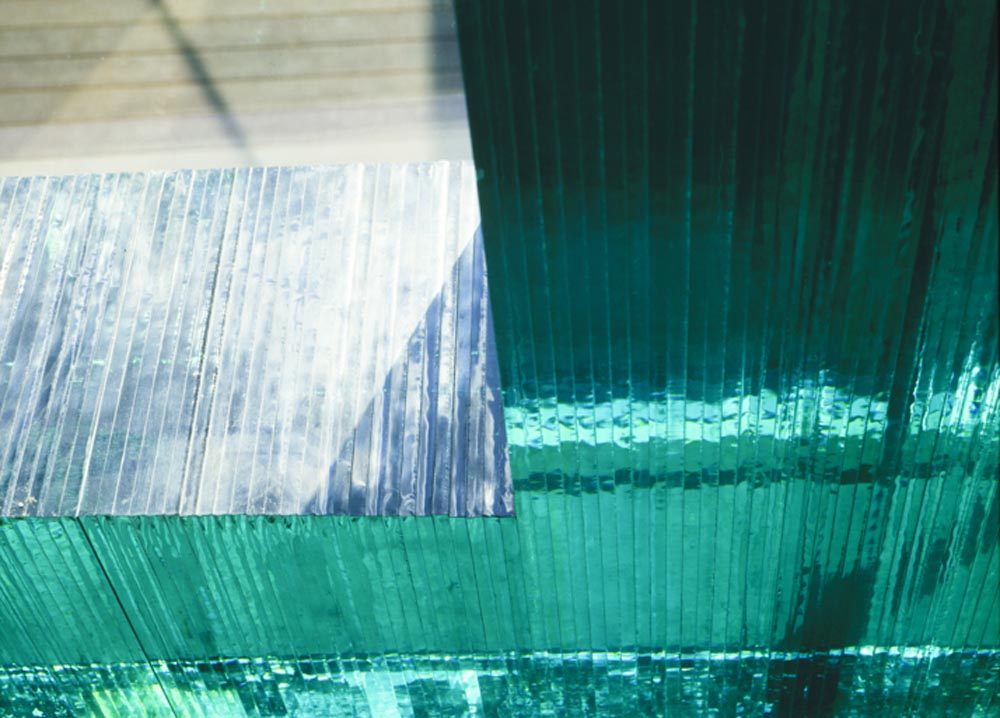

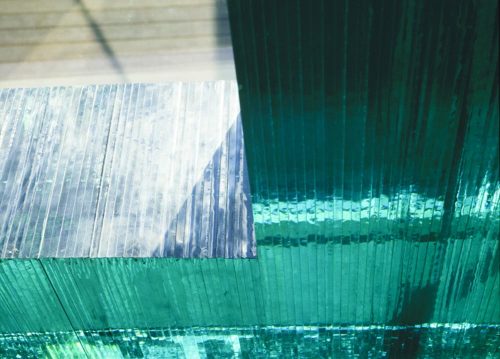

The walls are composed of individual layers of glass laminate about 1cm thick each, these blocks vertically stacked sheets are made of 10,000 individually cut and pasted into place with a silicone-based sealant.

The width of the walls varies between 20 cm and two meters. As for strength, but a single sheet can be broken easily by a hammer, taken together the laminated glass is stronger than concrete.

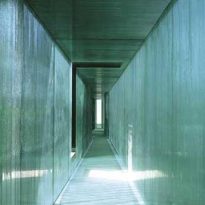

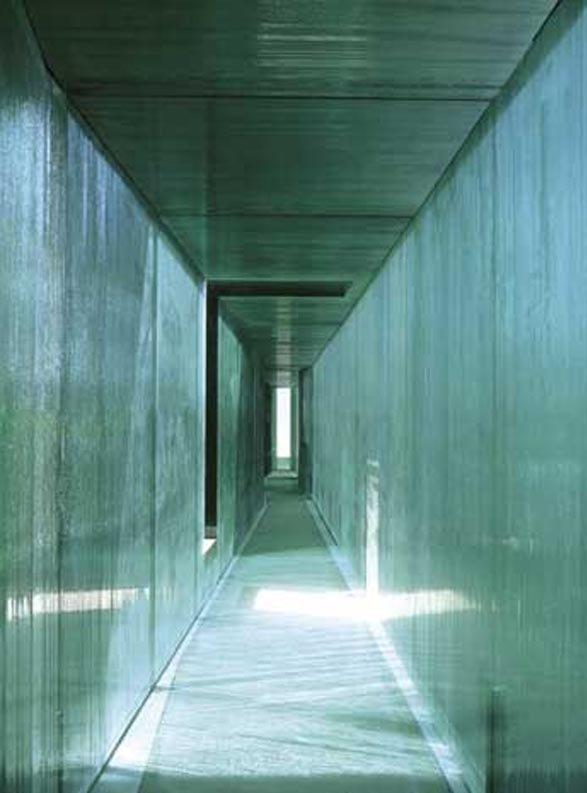

The curved path taken by the “knife” with which the crystal size is best viewed in the main lobby, which stretches north-south length and allowing access to the areas to be major. Here the ebb and flow of the mass of glass is visible on the exposed ends creating an unexpected pattern rich ripples across the surface of the walls, enhanced by the play of light and shadow.

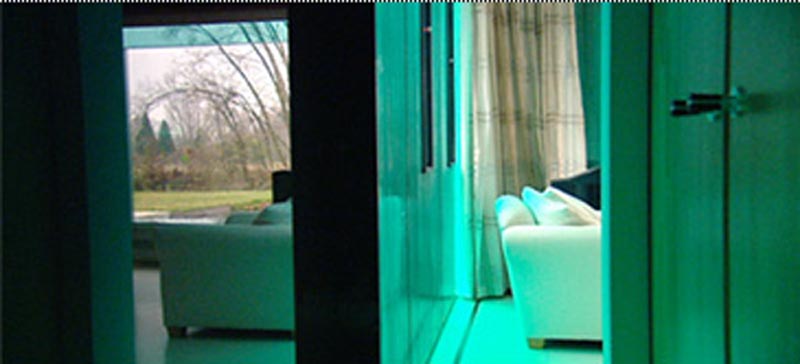

Variable light passing through the uneven thickness of the walls creates a striking effect from the opacity of dense protective walls thicker until the transparency of clear finest plates.

Laminate at home, the glass loses its fragility, becoming heavy and gaining mass and volume. The result totally redefines the use of glass as a building material and thus represents an architectural revolution.

The building sits on a concrete slab, heated through and below ground through an electrical system due to the inability to install it within the walls.

The thick walls absorb the increase and radiate heat inside the house, eliminating temperature fluctuations and the need for air conditioning in summer.

The glue

The long investigation of four and a half years, the development and construction program was in part due to the difficulty in finding a suitable glue which bind the sheets of glass. However, a revolutionary solution was developed to ensure that the glue used was resistant to UV and permanently flexible while accommodates the expansion and fragility of glass.

The experimental solution was the result of a unique collaboration between architects, the Netherlands Institute of Applied Science (TNO), based in Delft, which was responsible for the financial year of preliminary investigation, the company Saint Gobain Glass, which We manufacture glass and sealants Den Bravo, based in Oosterhout.