Villa Nurbs

Introduction

Villa Nurbs is a house located on the Costa Brava, Girona.

The architect, Enric Ruiz-Geli, is known for its anti-conventional designs in which combines movement of organic lines and complex geometries with new technologies.

This project has been awarded an Honorable Mention in Ceramics Awards ASCER VII.

Location

Empuriabrava is a neighborhood where housing is a morphing car space and space ship.

Occupation in urbanization is redefining the model plot.

Access by boat and car make it possible to think of an urban open, connected, free, that is, a single space.

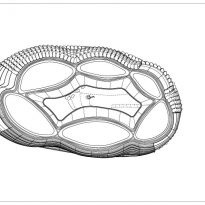

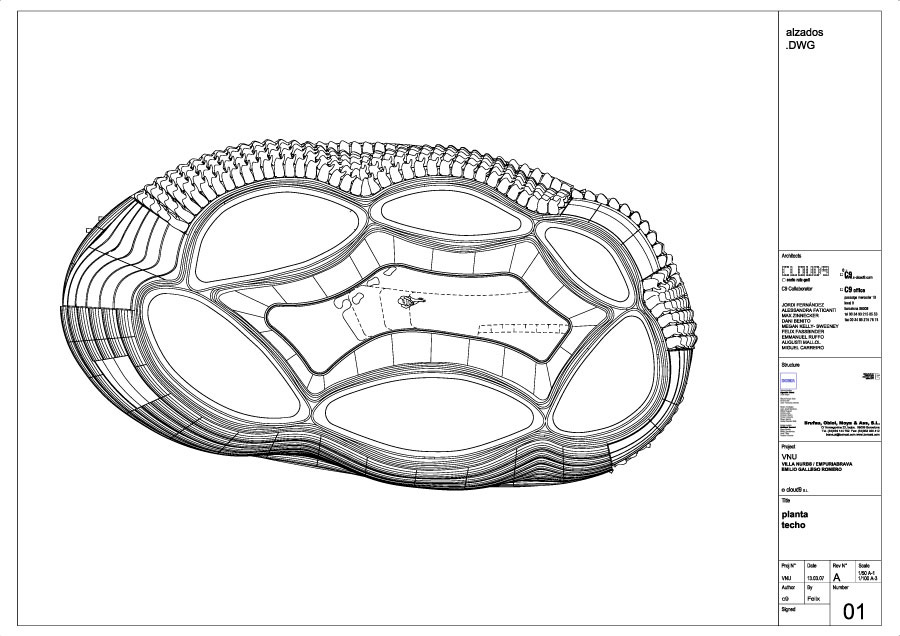

On a plot of 1800 m2, the occupation is minimal, only 130 m2. The living space rises from the ground to level + 3.50 m.

Concept

- Experiment with the crash of breaking the ice and get volumes of water.

- Find the natural material define a landscape, a landscape of pavilions.

- The construction of this landscape as a platform of dwelling.

- Measure and build that landscape and topography in 3D.

- The resolution of the topography of each contour and 5cm 45.15.

- The geometry is complex.

- Your goal will be a reference and NURBS.

- Find a new materiality.

- Optimize construction resources using CADCAM construction processes.

- The architect creates a platform that scales from the weather, geography, landscape until the skin outside of the home, the Nurbs.

- Industrial designers working guests from skin to skin Nurbs people, looking for the nearest cellular chemistry materiality.

- The design is always PARTICIPATORY customer.

- Definition of atmospheres within the skin.

- A skin “CONTENTS”. The skin has the ability to “engulf” home hardware

- CUSTOM TUNING: surface 3M adhesive that spherical glasses and serves as a reserve for interior painting. 220 m2 custom picture, only a plotter for the house.

- The skin is reactive and manages ENERGIES AND PRIVACY: tuning design also takes into account the demands of customer privacy and therefore reach an adhesive skin design through specific studies. Tours and movements of people, exposure to wind and sun in the different seasons. There is an abstract if not overlapping different diagrams.

- Democratize architecture “elite”, and bring the high-tech, the OpenSoft, housing.

Spaces

The main floor of Villa Nurbs is the type of a House Patio. The central element around which to develop housing programs, is an outdoor swimming pool.

Structure

Making Digital CAD CAM – Villanurbs

The way to build is CAD-CAM: The computer-aided design of Cloud 9 is connected to the computer-aided manufacturing, applied by the different project partners.

This process not only allows you to build things that were impossible before, but everything is a way to communicate and manage suppliers and engineers involved.

There is one-dimensional model of the project. In this model we get all the necessary information for the individual disciplines. It is a way of direct communication.

No general builder between.

No information is lost or precision on the road: The laser-cut piece is a translation from drawing to reality. Yet this production process is not standardized, and not all disciplines are connected to digital media.

So with every industrial, artist or engineer working on also has to invent a way to communicate.

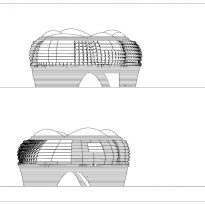

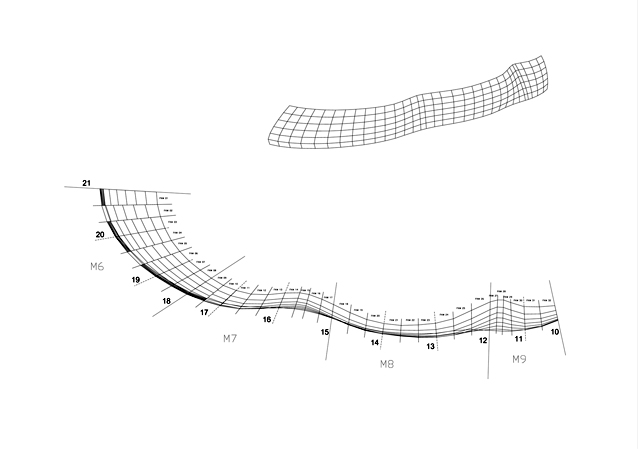

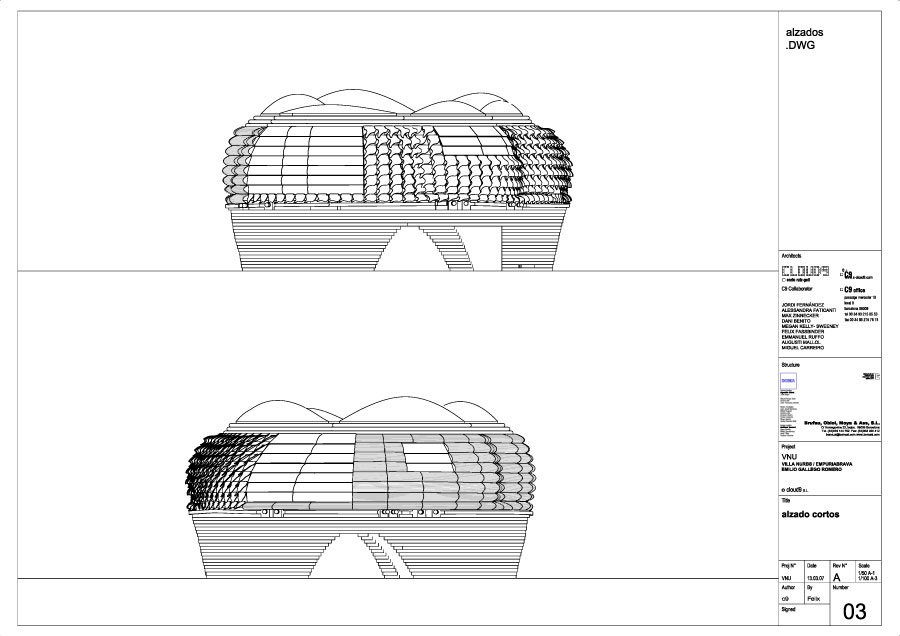

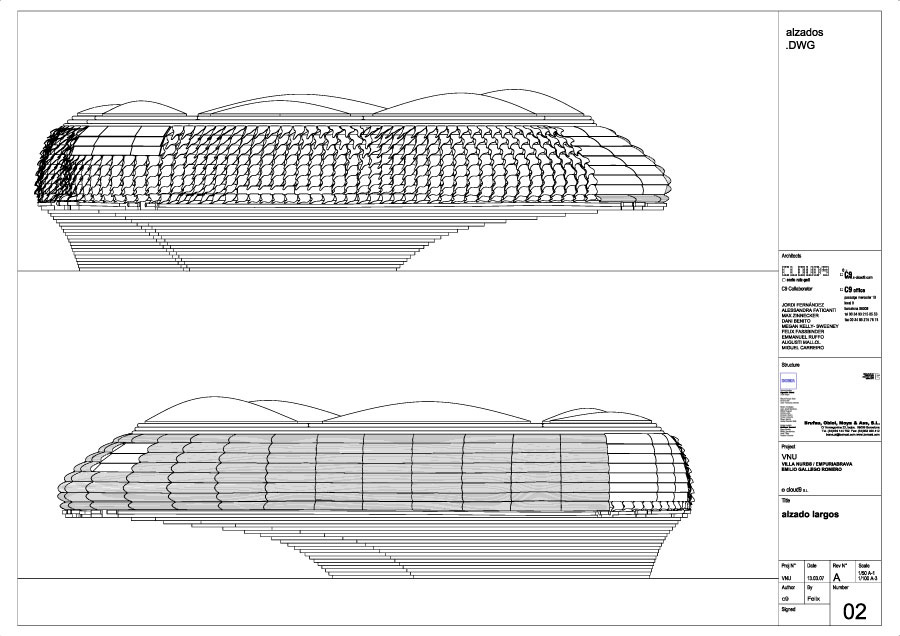

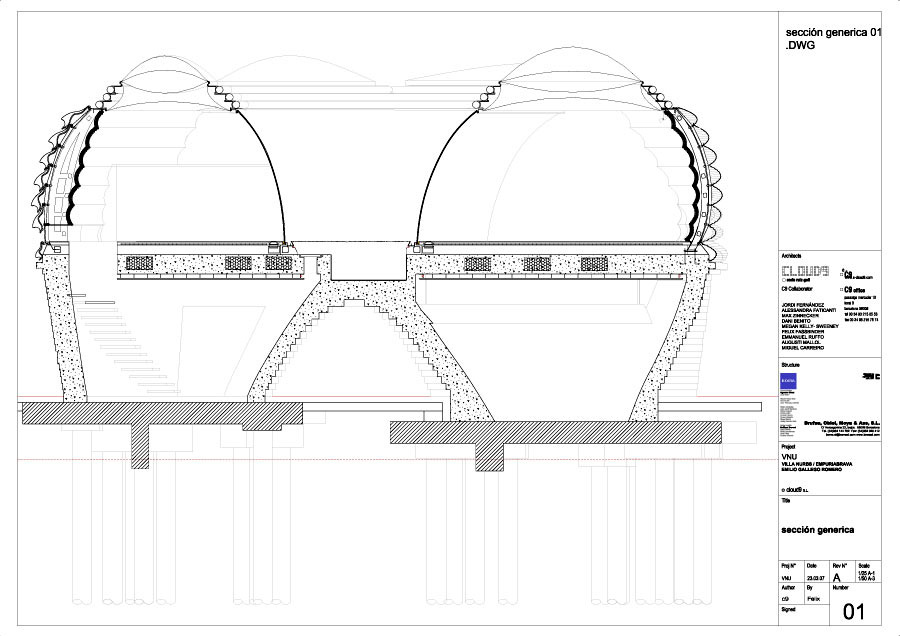

A reinforced concrete structure that starts with a colon and an overhang of 20 feet, with a resolution of 15 cm creates the platform for the living.

From this height, it generates a metal chassis and 45cm resolution, a model with the aerodynamics of the car, where it attaches and develops Villanurbs reactive skin.

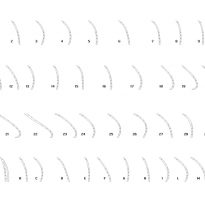

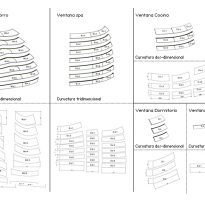

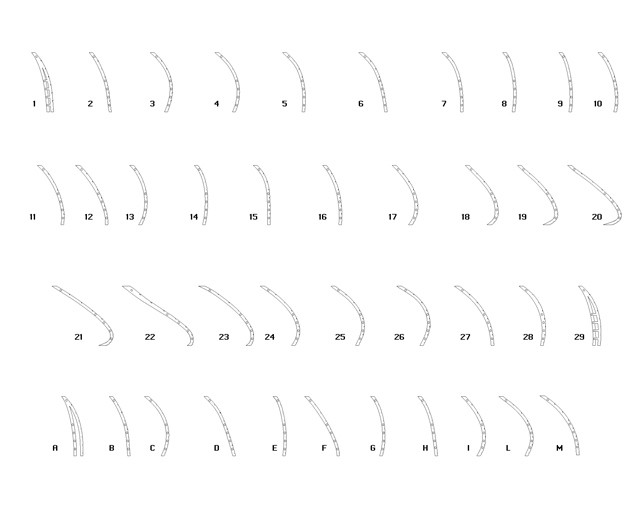

The design process of the skin has been developed in three phases of research:

- Study of the way.

- Production of the prototype.

- Study of the repetition of the prototype.

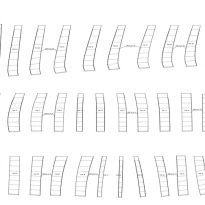

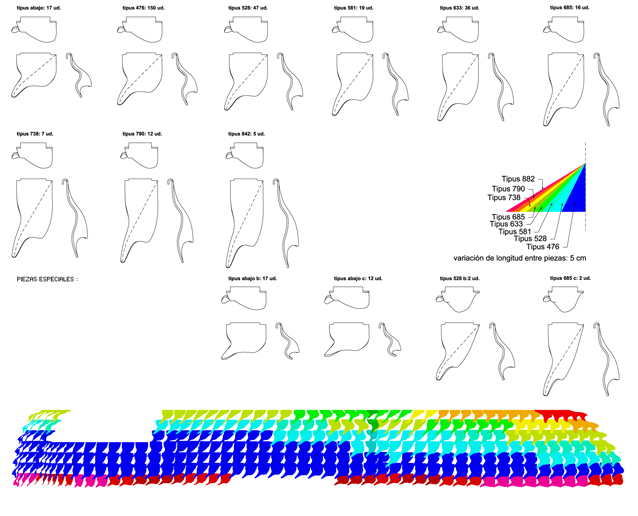

Form

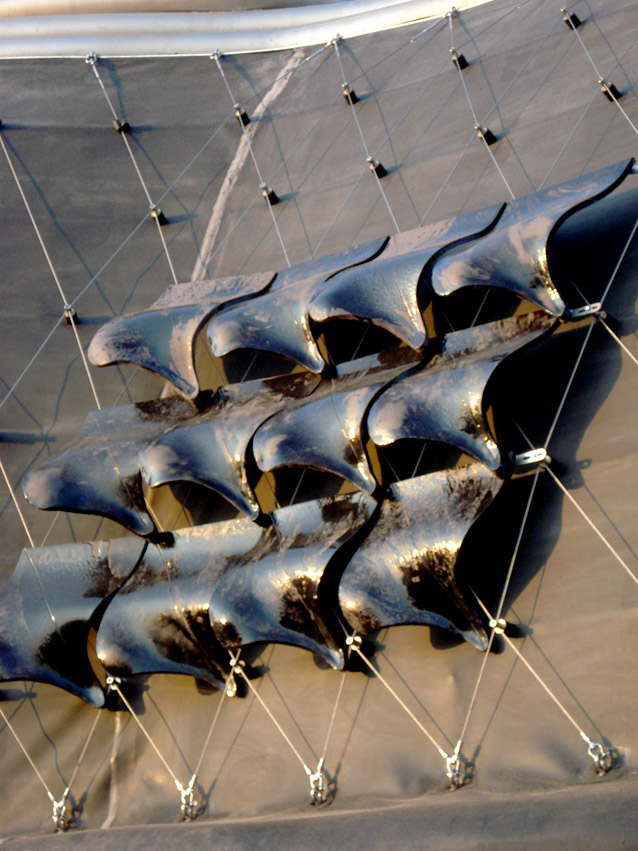

Although elements may be considered in the unit, their study as an integral part in a whole, has had to consider its repetition over the entire surface of the facade. Only in this way it was possible to perceive their behavior and function of the building facade.

Protection from sun, wind and rain and cooling of the facade were the main points considered for this study.

The resulting form this study allows skin to function as a set of sheets which protect the building:

- From sunshine.

- In the rain, leading from room to room by gravity.

- Shutting down the strong Tramontana winds from the mountain.

- And opening, while the breeze coming from the sea.

After development of the study on the shape of virtual three-dimensional model, also occurs on a virtual basis, the lower mold in this way.

This mold is then sent to the Whip Industries Vilà.

This company has a hardware and software that allows the practice of CAD CAM processes.

These processes involve a relationship between digital design software (computer aided design – computer-aided design – CAD) and machine software that enables the production model physics virtual (computer-aided manufacturing – computer-aided manufacturing – CAM).

Then, by reading the virtual model, a digital mill acts on a solid block of expanded polystyrene, transforming, through a process of subtraction, and copying of grinding sections in the physical mold of the piece.

The same CAD CAM processes are used to produce a display of aluminum piece.

Once defined, in Ceramics Cumella this way is used for cutting the sheet of mud then placed over the mold of polystyrene.

The mud is deformed by its own weight, thereby taking the shape of the mold.

On this piece acts deformed painter Frederic Amat, continuing the idea of accident present throughout the project Villa Nurbs.

Work with layers of black and transparent glazes, giving life to ceramics. With Frederic Amat defines the color and how to apply these glazes.

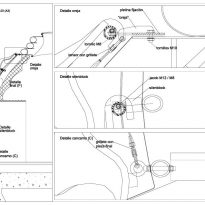

Study prototype repetition

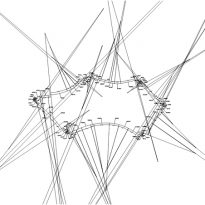

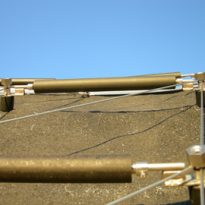

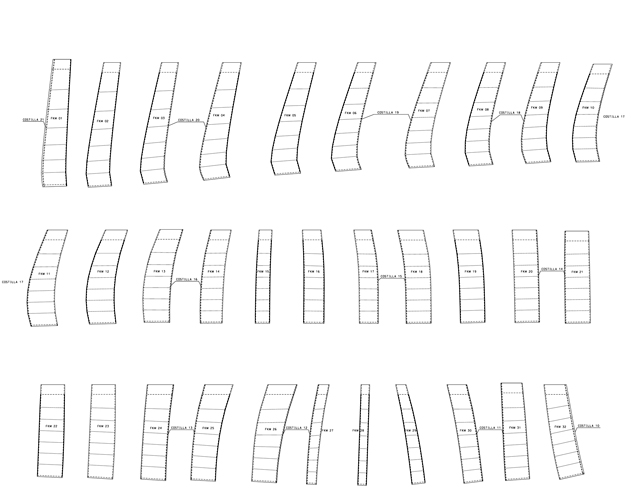

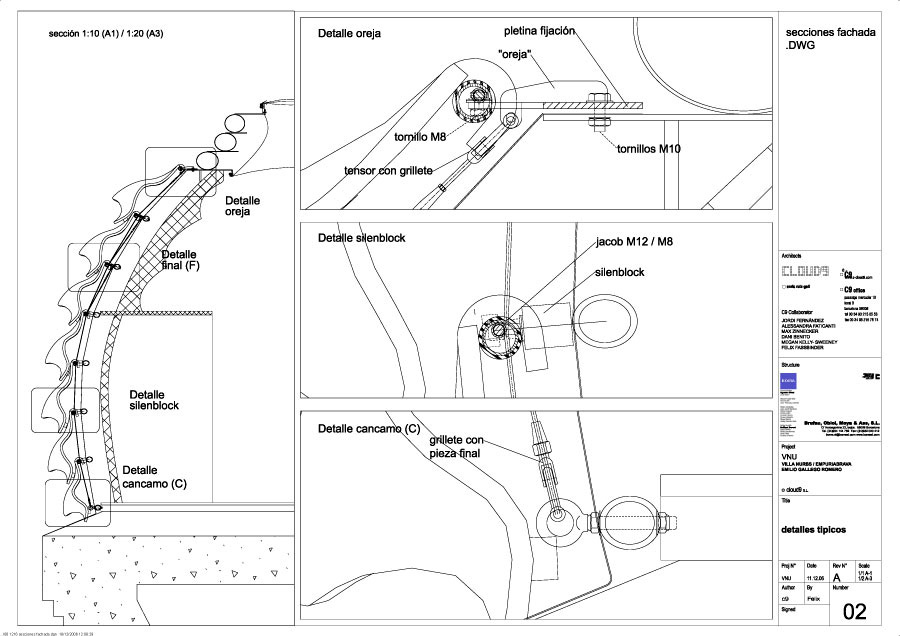

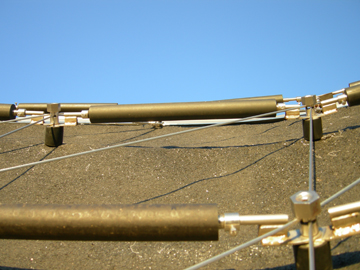

We have developed a system for attaching cable 406 to define the front parts.

In partnership with BOMA, estimator of structures, the features we have to behave this system so that the whole work.

A ceramic parts, suspended from a cable system, form a ceramic skin.

Materials

It has developed a process Cad – Cam for communicating digital design in Cloud 9 with traditional in Ceramics Cumella.

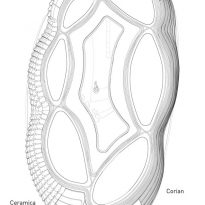

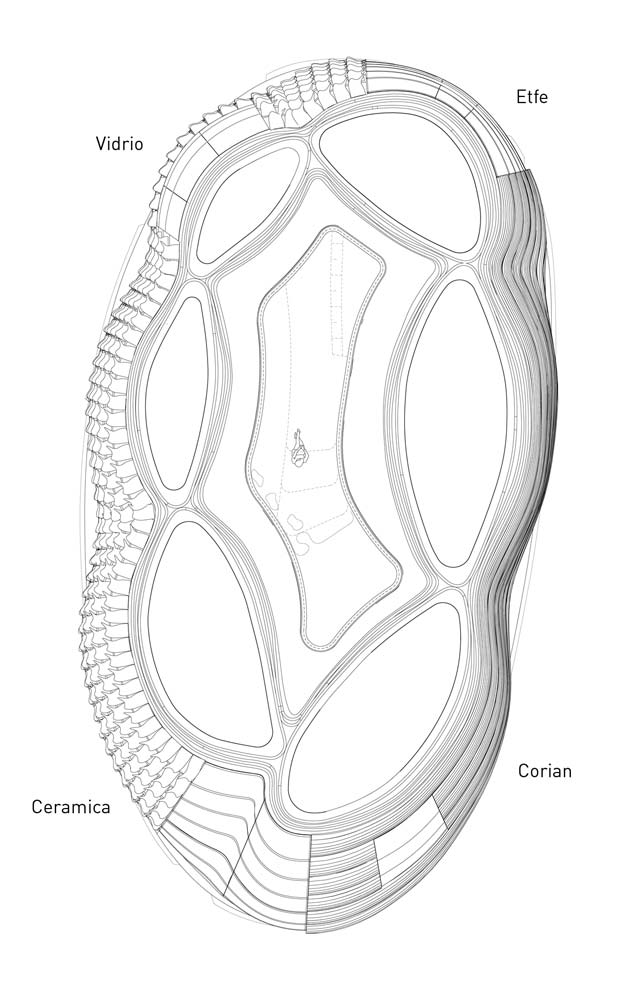

The facade – inside out – is made up of several layers:

GRG panels with PCM, and thermal insulation, air chamber, EPDM waterproofing membrane and ceramic elements.

GRG panels are self-supporting. Use the metal chassis of the first floor to the surface tension of EPDM, which is vulcanized with slate particles on the outside.

This surface is not pierced in any point, the entire mesh works by pressure to the structure. This pressure is what allows hanging the ceramic mesh.

To the northeast facade also redefines facade, from materials to the resolution thereof.

The skin develops a Milar waterproofing, less than 1 mm thick and is a continuous surface of translucent Corian that lets the warm light, and that develops Vilà Whip Industries, BEC and Boma SL Industries, working with the same process of CAD / CAM in the definition of each of the pieces of corian. In this case the molds used have a different density, are polyurethane, the plates are corian e = 6mm and termomoldean to achieve its final shape.

These are secured to the metal chassis via a tensioned wire mesh operating pressure.

This system has been developed to hold the cable 106 that define the front parts.

This allows at any point puncture waterproofing.

Ceramics

Villa Nurbs integrates art structures with ceramic, a material with a long tradition in architecture, both in the construction and finishing of buildings.

The production of ceramics intended for the north facade of the building was carried out by digital technology molds carved under the direction of Toni Cumella.

The pieces, whose form is inspired by the scales of a reptile or animal antediluvian pottery skin that form the building have been painted by Frederic Amat. Installation expert ceramic artist, ceramics Amat has become unique pieces of great aesthetic and functional value. Integrating traditional materials and generation, Ruiz-Geli has brought to the art industry.

Skin Glass

The main floor of Villa Nurbs is the type of a House Patio. The central element around which to develop housing programs, is an outdoor swimming pool. The separation between indoor pool and is formed of a curved glass wall.

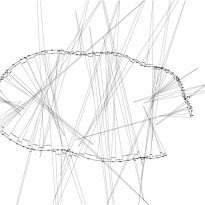

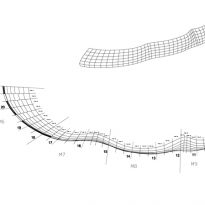

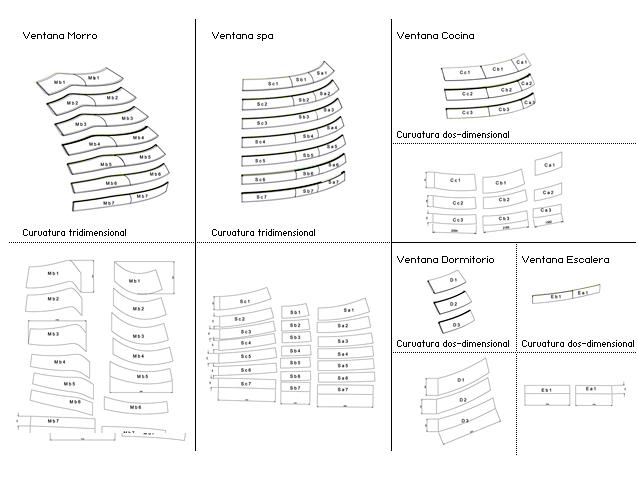

This wall sculpture is the most important element of housing. It is also the only element in which the surface “Nurb” is not subject to a process of simplification before production. It really is the production of 140 m2 of surface “non-uniform rational Bezier spline” (NURB).

– How to give materiality to a glass surface?

– That’s the time it entered the French artist / American Vicky Colombet in the project.

His work based on flows, particle movement caused by wind fits perfectly with the philosophy of Villanurbs.

It produces a paint film over one that is placed within glass laminates.

While giving materiality glasses Vicky Colombet painting also low solar factor. Also the film adjusts itself to the insolation: When there are more radiation, becomes more opaque.

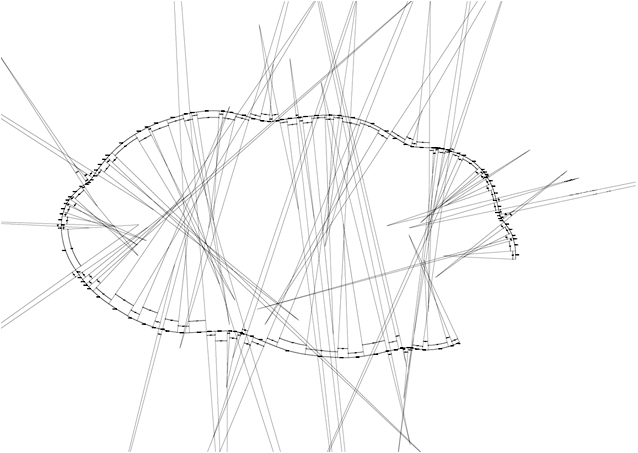

The complicated curvature of the glass requires a CAD-CAM work very coordinated. First a surveyor has to get the exact geometry of the existing structure, that is to move from the 3D virtual reality constructed. Thereafter CLOUD 9 produces a surface. Cricursa works directly with these digital files to make molds and glass displays. The molds are produced from laser cut steel cutting. Ship deployments Vicky Colombet. The serve as part of the job.

The construction system is increasingly Villanurbs light from bottom to top. The base is a post-tensioned concrete structure.

The first floor is formed by a light metal structure supporting a double ventilated façade, in total a very light structure, made of layers of material joined just 10cm.

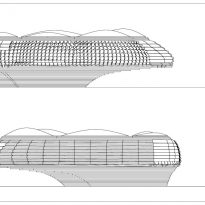

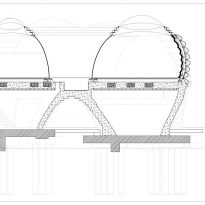

Inflatable

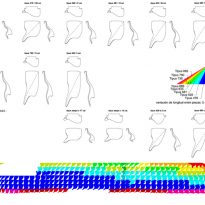

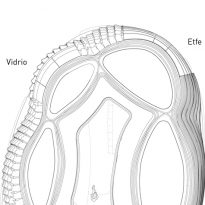

The cover is formed by inflatable – cushions ETFE films formed by air pressure between them.

The total thickness of the sheets sum 1mm.

It is a material that is commonly used to cover large areas, i. e. sports halls, shopping centers, botanical gardens.

The advantages are its high transparency, behavior self – cleaning and stability to ultraviolet rays.

It is the first time it is used as a roof for a single house.

Also required is an application that features other than normal use. It requires light control, acoustic and thermal insulation.

Investigating a light control tire, through changes of air pressure either let light through or get an opacity of 98%. Cushions used with several layers which greatly increases the heat insulation. The lower air chamber does not work with on – pressure, but with “negative pressure”.

The effect of vacuum is used: In the absence of material does not pass noise.

The process goes both CAD CLOUD 9 and in the enterprise Covertex. CLOUD 9 proposes the system and how the cushions. Covertex ago elasticity studies to find the logical form of the inflatables. Through a display element of the 2-dimensional plane is a exploded then cut with cutting tables CAM.