Sclera Pavilion

Introduction

As part of the London Design Festival, each year a project is exhibited Size + Matter section, which aims to challenge the public perception of everyday materials, by creating spectacular outdoor temporary structures.

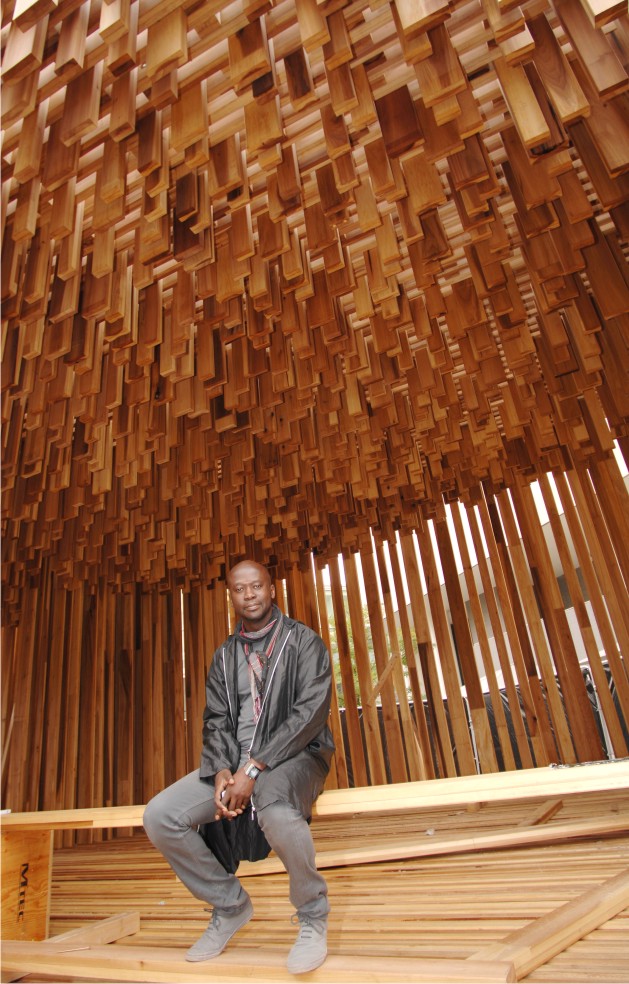

In 2008, the section was chosen for this David Adjaye, who created the Sclera Pavilion. In collaboration with the American Council Hardwood Export, the architect chose the tulip-wood for his work. It presents well, the prototype of a new material that has never been used as a building material external.

The work is characterized by an innovative design that leaves no one indifferent, giving versatility to a material often used for more mundane buildings. Explore the possibilities of designing a unique space from a design element “simple” as are the tables timber.

The term Sclera (sclera) is defined as whitish membrane covering the eye with an anterior aperture that crimps the cornea. Sclera is where the light gathers, a transitional space where light becomes information. The architect chose this name to make reference to a “space from my point of view.”

Status

Located meters from the Royal Festival Hall, on the River Thames in central London.

Concept

The architect interpreted the meaning of Sclera Pavilion as a “space of my point of view”, highlighted the relevance and abundance of open areas in the design, whose sense of space and freedom are enhanced by the lightness of timber construction. The structure blurs the boundaries between architecture, design, engineering and sculpture.

The design is inspired by the idea of optics, how the eye receives and perceives light, how to reach the eye and how it affects the emotions, so the architect decided to make a light box.

The project explores the use of light to create a modular and space from light and shadow. But a picture is pixelated, as if he were still in training. It is necessary for the visitor, once set the stage, experience the space.

Cylindrical shape was chosen because of the absence of angles, the ability to orient to any point of view, since the option of operating as an endpoint in a landscape. It was conceived as a cylindrical chamber that modulates light around through this material.

The work was based on using a material that would explore all aspects of construction, from the structure to the coating and decoration.

Spaces

The work measures 12×8 meters. Is elliptical, like a great eye that visitors can explore and experiment.

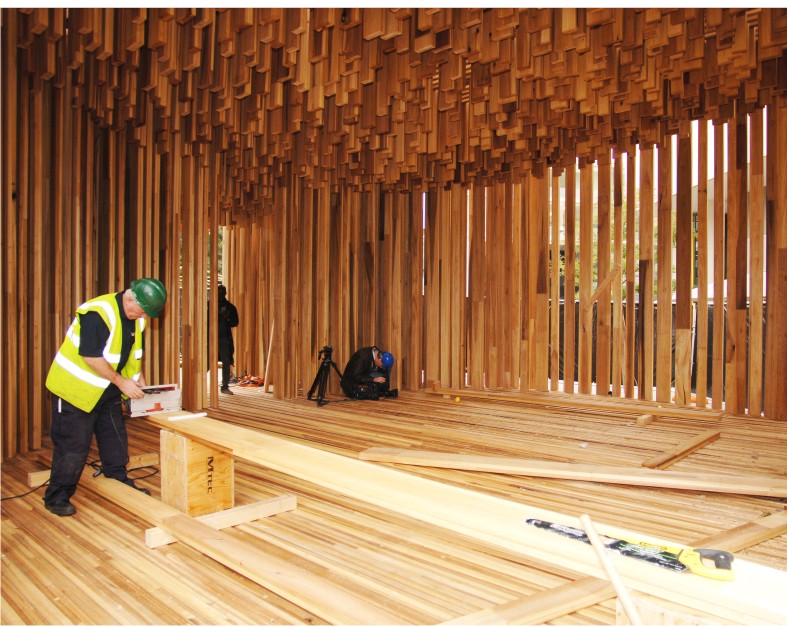

The curved forms that define the volume of the pavilion was built with the position and size of the tables, while the separation between the same levels of permeability lighting set variables based on weather conditions, time of day or the viewer. The elliptical shape is created additively with straight pieces of wood, without resorting to material deformation curve. The dimensionality of the roof was not worked with random lengths, but a piece of composition, creating a spatial phenomenon.

The pavilion consists of two circular chambers. The lateral entrance to the first chamber leads. The second, larger, creates a strong sense of space. The entire interior offers visitors an experience of spatiality transmitted by the elliptical shape of the wall and the floor and ceiling dimensional smooth curves. The clarity of the wood and the shapes and spaces provide an intense sensory experience as the visitor moves through the work.

The larger chamber is the center of the pavilion. An opening in the wall, framing the view to the outside. This perspective explains the second interpretation of ‘Sclera’ as the term used to designate the ‘membrane with a front opening that crimps the cornea’.

Structure and Assembly

Both the construction of the pavilion as an assembly required great skill.

Based horizontal street, nine supports are placed on the floor and a raised floor wood. Then we proceeded to lift pole 370, of different sections and up to 4.50 meters of casing length supporting the vertical ellipse. The posts are fixed to the base by pins, together with the roof element. A total of five fastening systems are responsible for side loads absorb horizontal forces.

The roof is formed from nine essential elements. On the poles 370 are positioned ceiling joists 68, each with a section of 6 x 24 cm. 910 planks, apparently random lengths, hanging from the ceiling creating an undulating shape and being responsible for the three-dimensional effect. Since the planks suspended part of the prefabricated elements, its position should be made with great accuracy. To achieve a permanent and secure fixing to joists, used a special numerical control unit that automatically dials and with a high degree of precision the positions in which planks finally bolted.

Materials

Liriodendron, also called Tulip Tree, is a genus of plants of the family Magnoliaceae. It consists of two species of large deciduous trees, a native of the East Coast of North America, the other from China. The Tulip Tree is one of the most prolific trees United States.

Tulip Tree is a renewable hardwood that is used more as a reference material for finishing and detail because of its changes, and there is no assurance that a particular color. The pavilion is a way to show how you can enjoy a wide range of use of this species.

Thanks to the sustainable management of forest resources Americans, always growing volume exceeds the volume felled in forestry.

The wood has great advantages such as resistance, retention of chemicals which facilitates the application of treatments that improve, and long lengths of material, completely free of knots. In this case, was used as a new treatment typically has a limited lifetime outside. This decision breaks new ground in material applications because so far only been used in the manufacture of furniture for interior joinery and kitchen cabinets and doors.

For the construction of the pavilion was used approximately 50 cubic meters of wood American Tulip Tree, supplied by American Council Hardwood Export, weighing 25 tons.

Despite being a stable species, all sections except pavement elements were fabricated with two face sawn boards glued with resorcinol adhesive offering good weatherability.

To achieve effective protection against weathering, the parts are sprayed with a primer first Prime GN. Then he tried a dunk tank, with an oil primer manufactured by Osmose. In the case of larger items, the application is performed with a brush.

Videos