Kresge Auditorium

Introduction

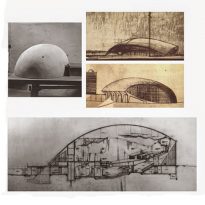

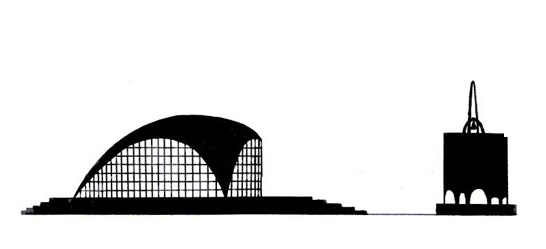

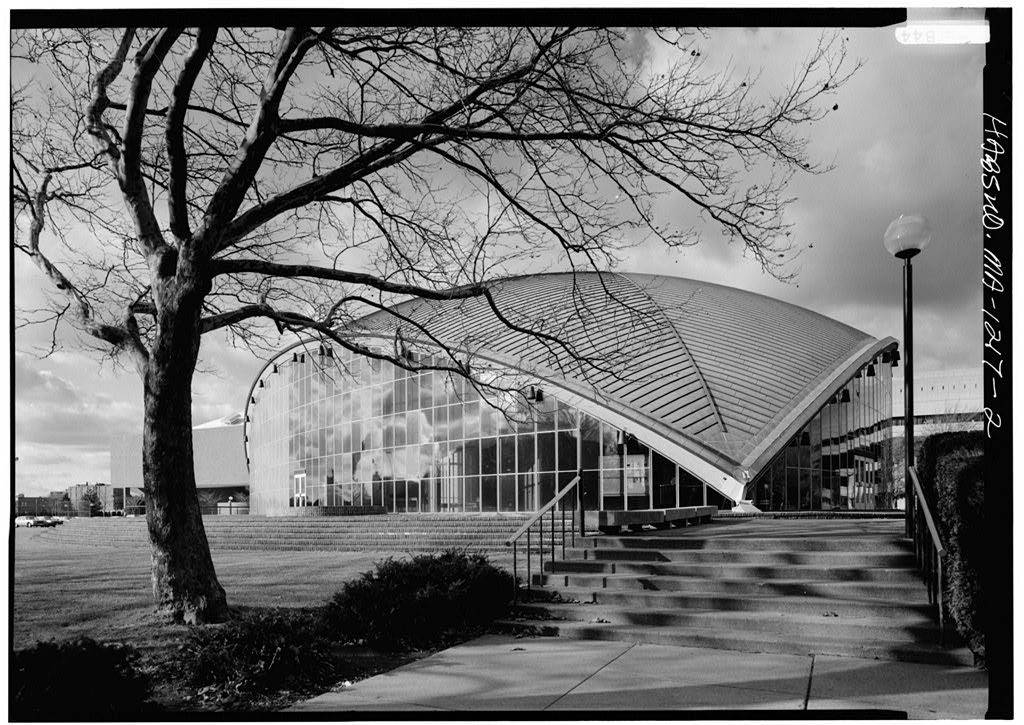

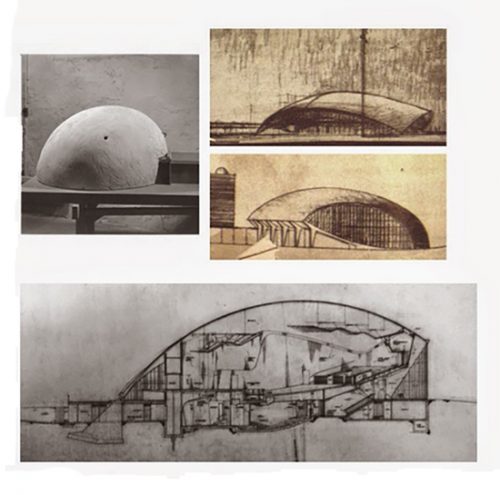

In 1950, Saarinen began designing the Kresge Auditorium and Kresge Chapel of the Massachusetts Institute of Technology, choosing to do basic forms, one-eighth of a sphere for the audience and a cylinder for the chapel. These works marked the beginning of the search for the architect to the significant and indicative of public buildings. The Kresge Auditorium, whose alternative name is building W16, is defined by an elegant structure of thin shell, one-eighth of a sphere which reaches a height of 15.24m offering an unobstructed view to each viewer, as there are no internal supports for the arches of the dome.

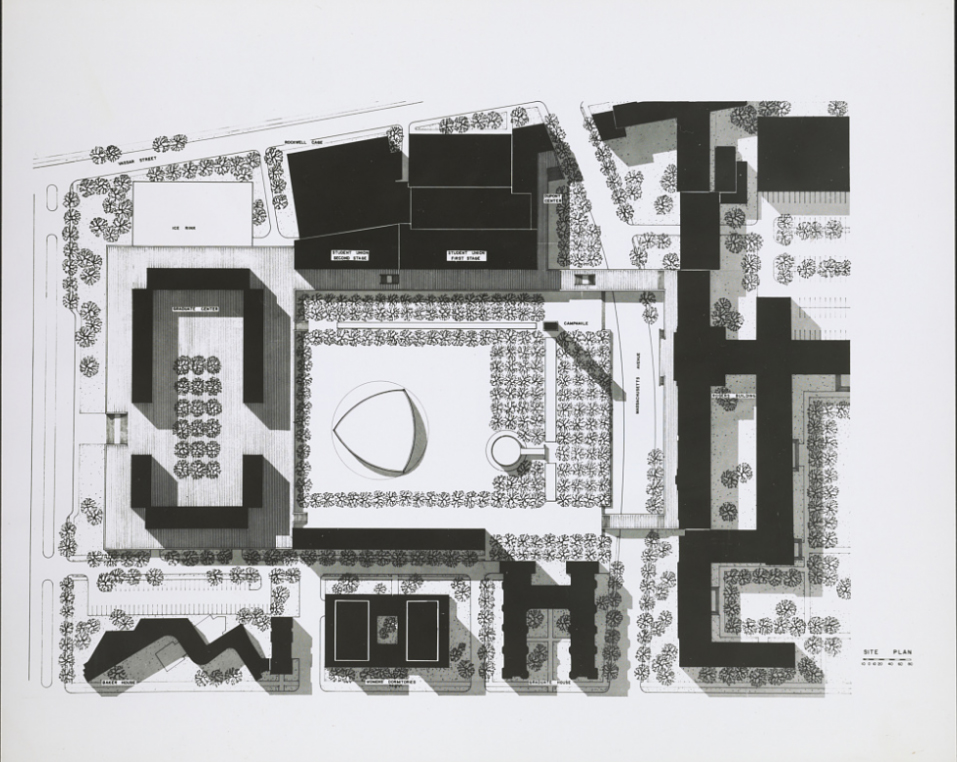

Location

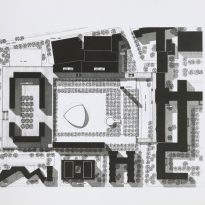

Like the MIT Kresge Chapel, the Kresge Auditorium is located within the Massachusetts Institute of Technology, MIT, located at 48 Massachusetts Avenue, Cambridge, Massachusetts, United States, separated from the chapel by a green area. The campus borders the Charles River and has views of Boston downtown.

Concept

The idea of the dean of the school of architecture at MIT was to create an area on the field that would serve to bring students to organize parties, weddings, offices of various religions and social gatherings. To this end commissioned Saarinen the design of a non-denominational church, an auditorium, a social space for students and a place to serve as a link between this space and Massachusetts Avenue in Cambridge.

The design of the Church, such as the Auditorium for the MIT were architectural experiments about which Eero Saarinen says: “… looking back to these early works, I think that the dome of the Auditorium and the Church can be criticized for being too egocentric. The shapes of the buildings are closed. Contribute nothing to create a unity with the environment. From the beginning, we think these buildings on a large square, but forgot to define and crystallize as achieved exactly, should have done… ”

“… The strongest and most economical way to cover an area with concrete is with a dome and a dome with a thin concrete shell seemed appropriate for a college interested in technological progress…” (Eero Saarinen, 1955)

The buildings are named in honor of Sebastian S. Kresge, founder of Kresge Stores and Kresge Foundation, which provided funding for both buildings hoping to serve as a nexus for social, cultural and religious life of MIT.

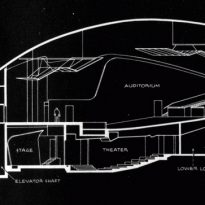

Spaces

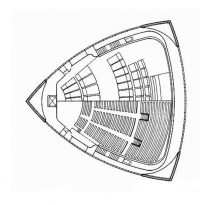

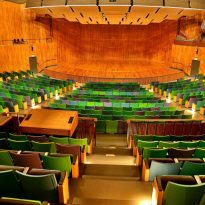

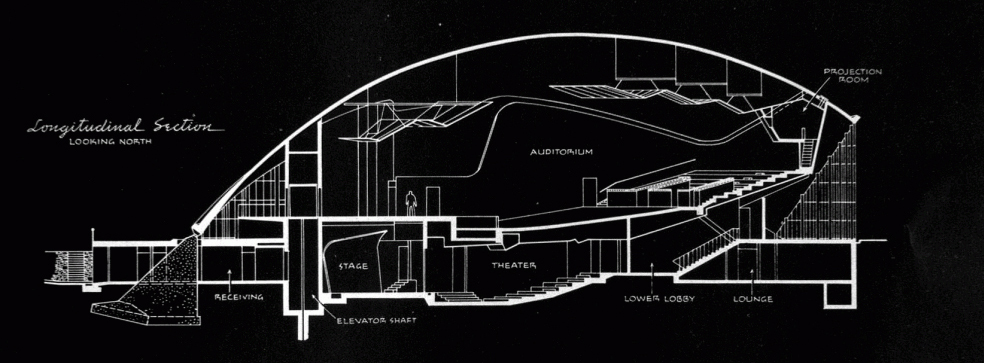

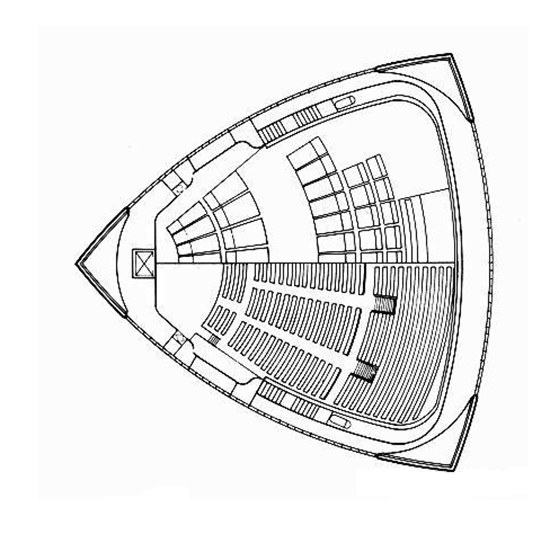

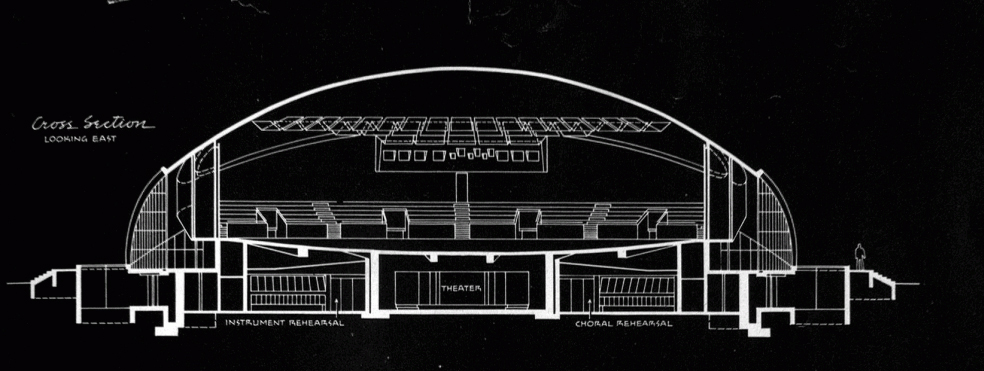

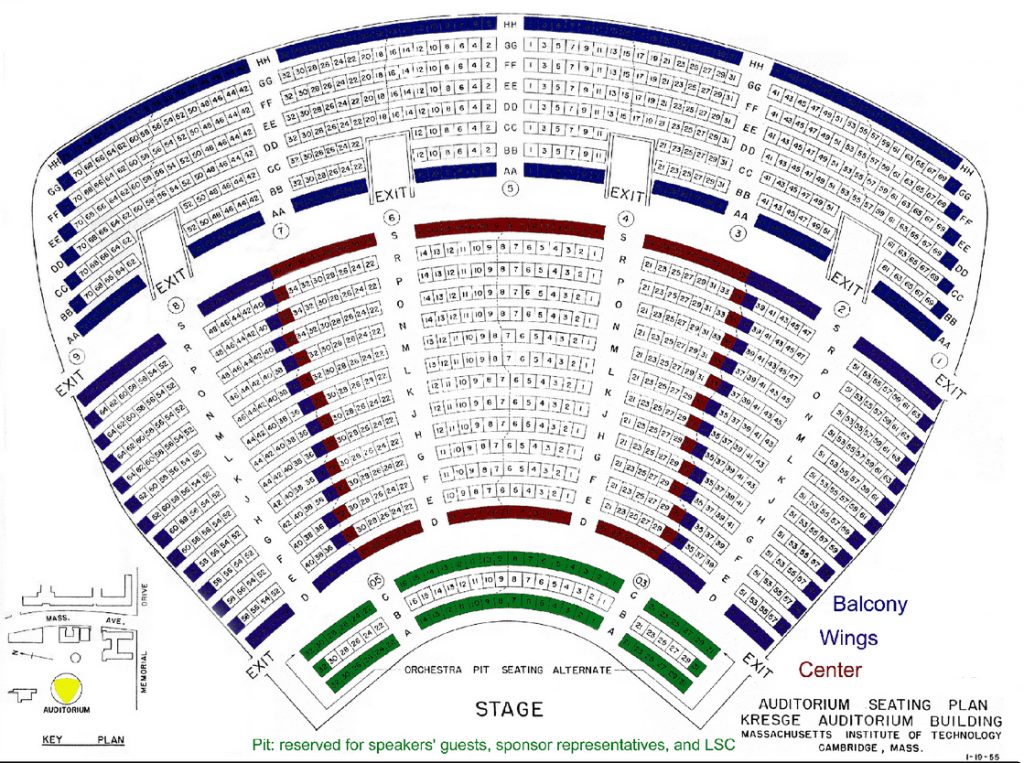

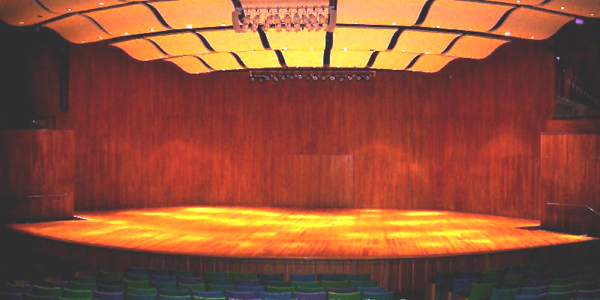

The Auditorium houses a small theater with capacity to 204 seated spectators, the concert hall and rehearsal rooms. Access, on the ground floor, opens onto an elongated hall, an intermediate zone between the lowest small theater level and the highest auditorium level. Also on the ground floor are a rehearsal room, a living room, locker rooms, a wardrobe and a small shop.

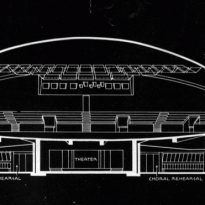

The largest room has a maximum capacity of 1,226 people, but when the stage extends over the section of seats, there are only 1,144 available. It is used for concerts, lectures, conferences, plays and other important events. The acoustics of the main room Saarinen worked with the Bolt, Beranek and Newman architects who resorted to enhance the sound hanging “clouds” to absorb the direct sound on stage, rather than the traditional plaster ceiling. These clouds also contained lights, speakers and ventilation. The walls are lined with natural wood.

Structure

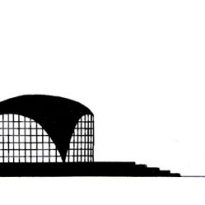

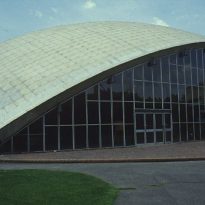

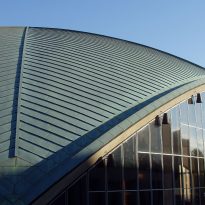

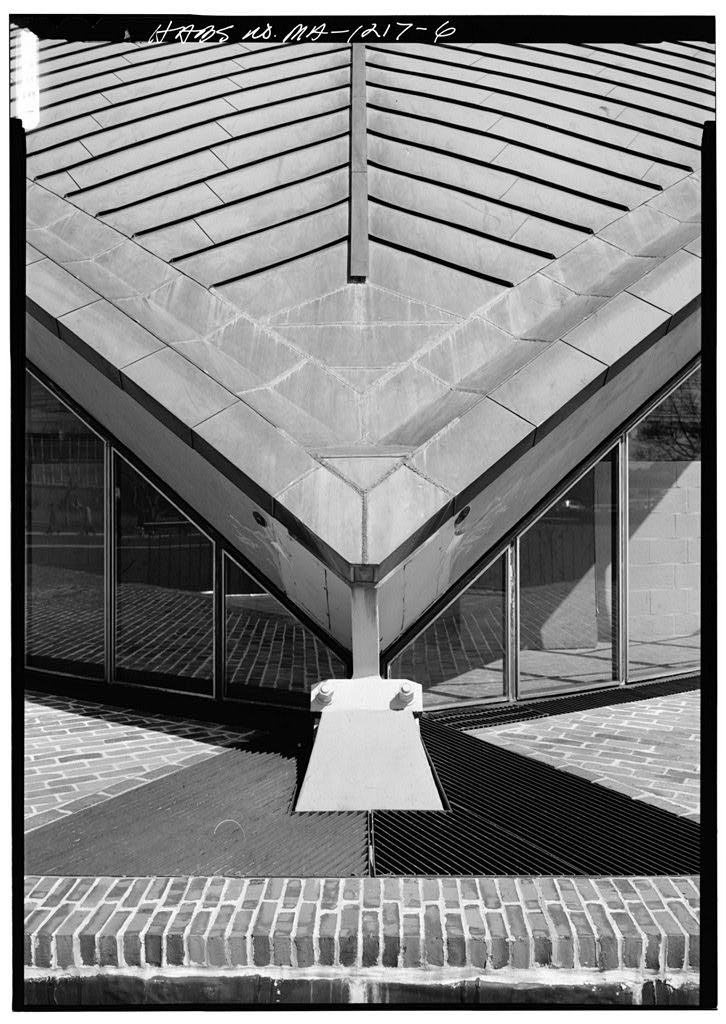

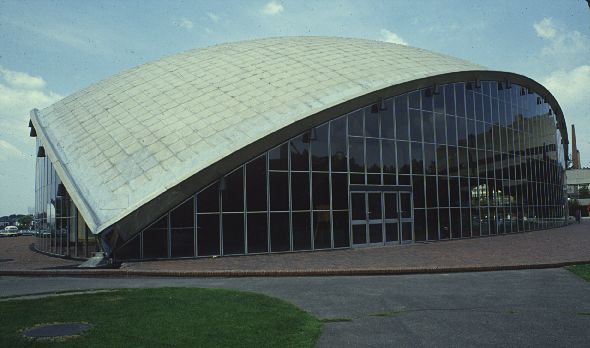

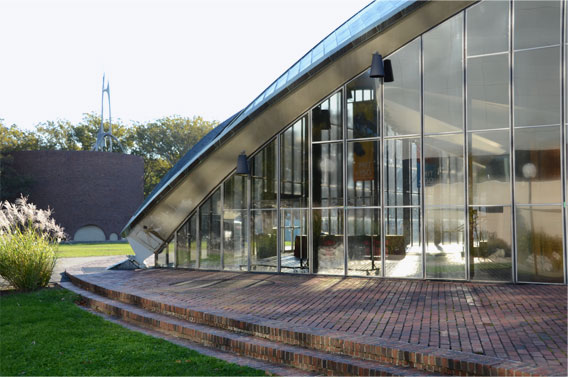

The auditorium has a stylish coated copper roof springing from the ground at three points with transparent glass walls that fill the arches created by the shape of the roof.

The distinctive design detail was marked by its elegant dome, 12tn, originally white, eighth of a sphere is anchored on points that remain hidden, shaping a thin cover with a triangularizado plane. In the three faces that form between the pillars high arches that rise to meet the concrete shell, creating three glass facades of the building are deployed. The thin cover Kresge Auditorium was the first built on a large scale, this method for a Public Building.

The truncated dome enclosing a triangular space of about 2023.4m² which reaches a height of 15.24m. With the primary structural ceiling that varies between 7 and 18 inches thick, the resulting span is 34.50m. Rigid reinforced edge along the perimeter beams defining the roof and large, solid transparent facades. A second non-structural layer, with the average thickness 6.35cm, lightweight concrete was used as a substrate for the cover.

The project had to face numerous tests, both during and after construction. The roof, originally intended to be supported only by three major carriers, required the addition of vertical structural pillars behind the glass, as the deflection of the edge beams was higher than expected.

Reviews

Both the chapel and the auditorium were not well accepted by the public at the time, which you received with much criticism, highlighting the negative aspects of its construction. These drainage through the roof in the auditorium. The shape of the roof and edge beams caused the water to flow naturally to the three support points. Due to inadequate mixing in concrete filled deck, in the original roof began to leak water, and soon to pass to the walls. This last fault was quickly fixed by replacing the existing roof with a new copper resisted until 1961 In 1963 the building was again renovated.

Continuous filtration of water through the years has caused other problems such as corrosion of reinforcing steel structural frame, until a complete structural renovation was necessary in 1979.

Materials

In the dome construction has been used reinforced concrete and copper plates. On the facades glass curtain walls were placed. The auditorium stands on a round concrete coated with red brick.

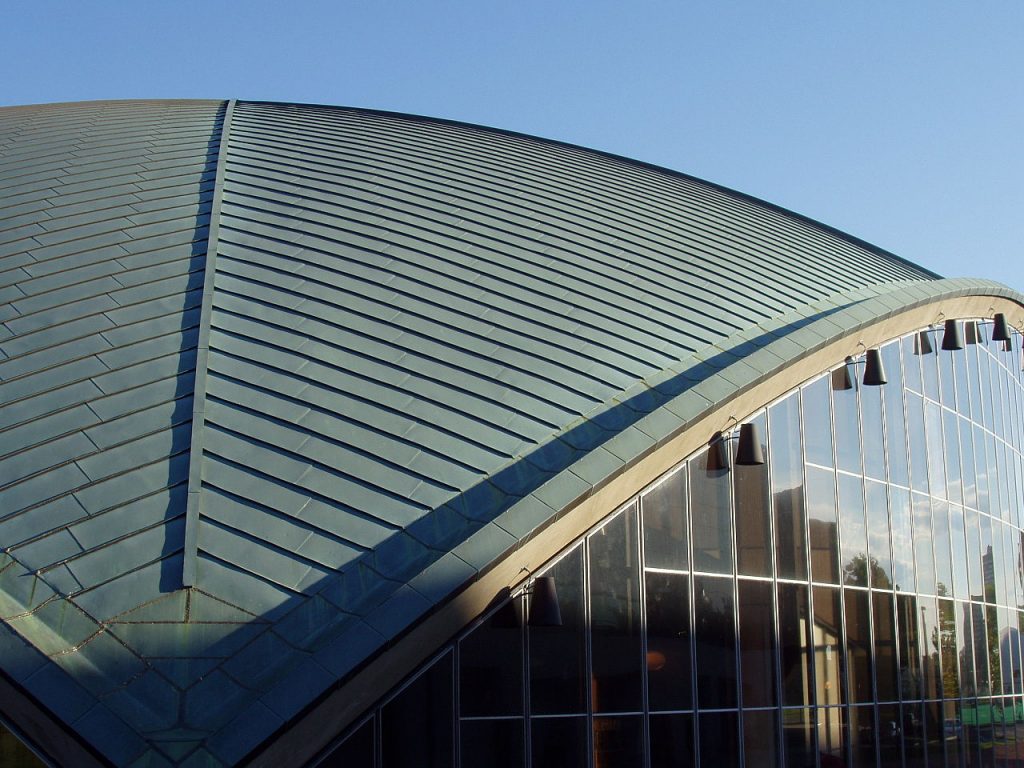

Roof coating

Finding the right material for the lining of the dome of double curvature represented a challenge. At first it was thought marble tiles and plates coated copper lead, but were rejected for reasons of budget and performance issues. He was finally chosen a cover created with sheets of limestone mixed with liquid acrylic polymer, getting a shell of a “pure white”

In 1963 the thermal motions had left their mark on the building, numerous cracks and delamination, turning the original roof unusable. Square sheets of lead were installed. Water infiltration through the lining of lead precipitated severe deterioration due to freeze-thaw cycle. In 1979, the concrete and reinforcing beams near each edge replaced mainstay. Meanwhile, the cover boards were filled copper.