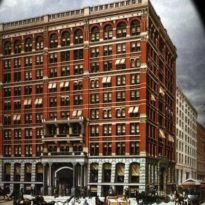

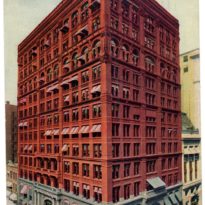

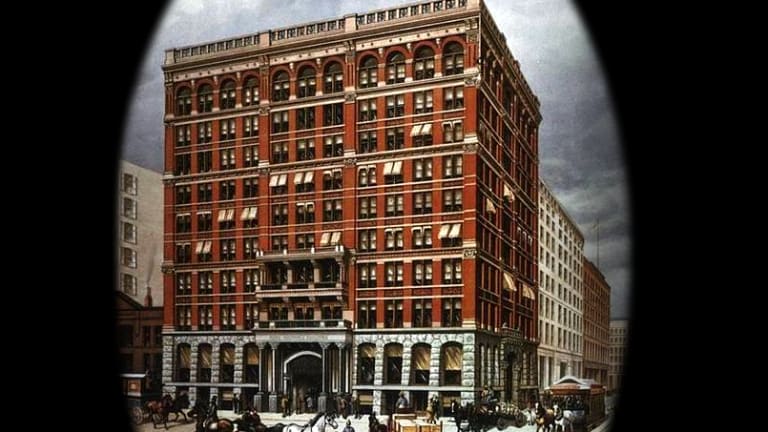

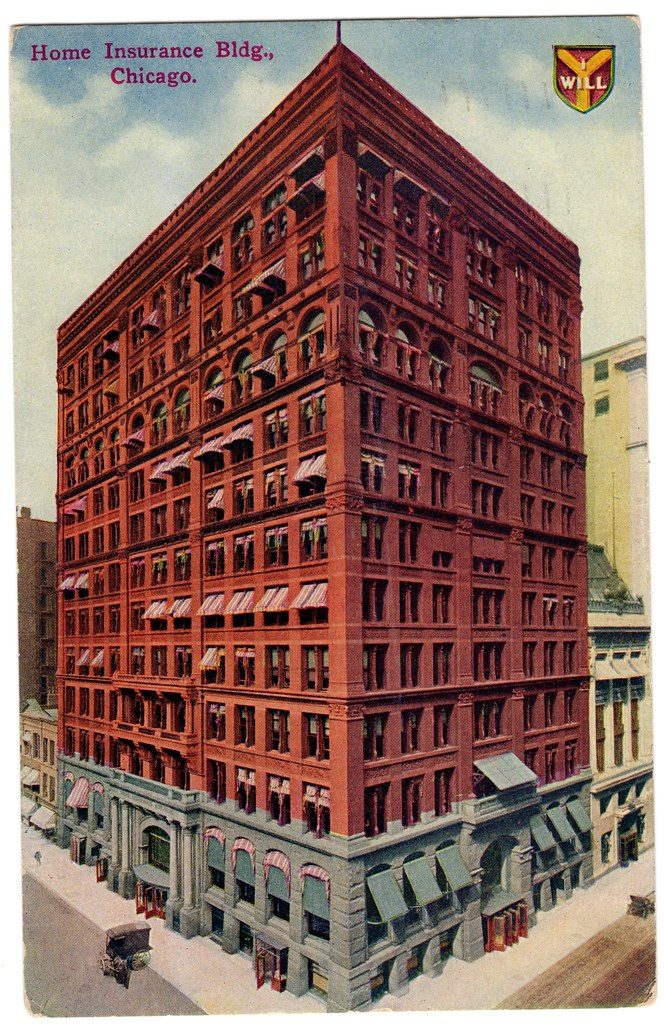

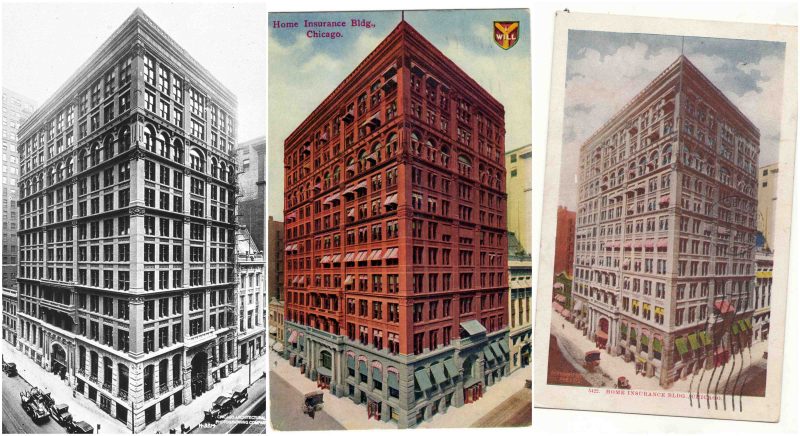

Home Insurance Building

Introduction

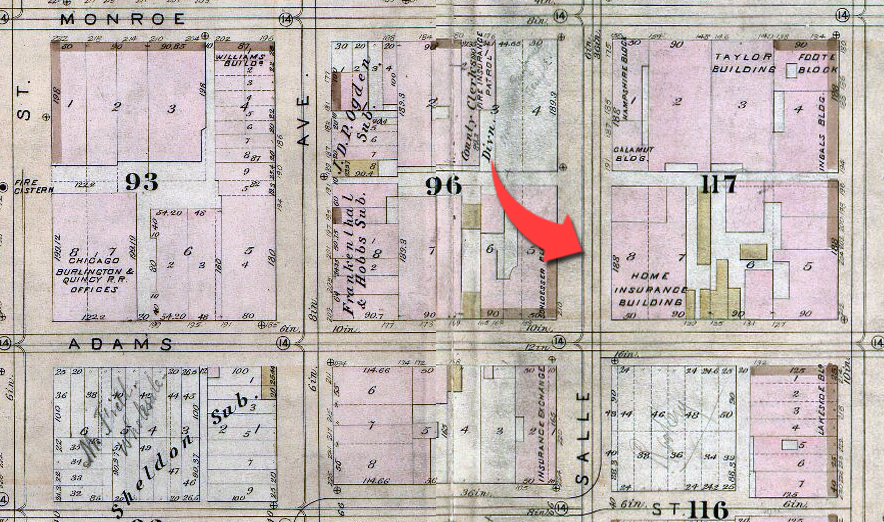

The exterior use of iron skeleton framing has been central to the historical reputation of the Home Insurance Building, giving rise to the claim by some historians that it was the first skyscraper. The project was initiated by Edward C. Waller, who had been a close friend of Daniel Burnham. While Burnham had chosen the path of architecture, Waller had gravitated to real estate development and had gained a reputation as a major player in Chicago properties. Waller had assembled the lots on the northeast corner of Adams and La Salle during 1883 for the British-owned insurance company to erect a new office building.

The company held a design competition in February 1884 that was managed by the company’s Chicago agent, Arthur C. Ducat. Ducat had been a major in the Civil War, during which he had made the acquaintance of William Le Baron Jenney. Had Jenney not been a good friend of Ducat, it is reasonable to assume that Jenney’s career would have faded into obscurity. Instead, Ducat gave Jenney a chance to design his first tall office building.

Location

Chicago: the northeast corner of La Salle and Adams Streets.

Concept

Jenney had actually published an article in 1883, in which he revealed his understanding of the use of iron members just before he received the Home commission: “Educated architects particularly in Europe… have been working with and writing on the combination of stone, brick and iron, in the street elevations of buildings.” He spoke of embedding iron sections within masonry piers, and not of wrapping an iron frame with a veneer of masonry. This combination of masonry and iron clearly reflected his French training and familiarity with French theorist Viollet-le-Duc‘s ideas. Therefore, Jenney’s conceptual understanding in 1883 of the use of iron in tall buildings, was not formed around the concept of the iron frame, but on using iron members to supplement the structural masonry in the piers of a building’s exterior. Even after the Home Insurance Building’s completion, he had stated in an article in the December 1885 issue of Inland Architect that “a square iron column was built into each of the piers in the street fronts.”

Materials

The first two floors of the two street fronts consisted of solid granite piers, battered in thickness from 4′ at the base to 2′-10″ at the third floor. The detail in which Jenney departed from standard Chicago construction of the early 1880s was his insertion of a rectangular iron section within the masonry piers in only the upper eight stories of the two brick and stone street facades.

Spaces

In plan, Jenney lined both the 138′ frontage on La Salle and the 96′ Adams Street front with single-loaded offices. This left a large void in the middle of the site that Jenney used as an exterior light court, that allowed the addition of only three more offices per floor.

Structure

The two masonry bearing party walls that ran the entire height of the building on its north and east lotlines, as well as the interior iron cage, were typical for the period. Jenney‘s objective was to minimize the size of the masonry piers in the office floors in order to maximize the daylighting of the interior office space. Therefore, he inserted a cast iron section within the exterior masonry piers in the two street facades. These were story-high, hollow rectangular cast-iron columns that supported the floor beams. The iron columns were set on top of the granite piers at the third floor and were bolted one on top of another to support the upper seven floors and roof.

The columns were cast with projecting shelf brackets to support the appropriate horizontal framing members. Two 12-inch wrought iron I-beam floor girders sat on a ledge at the interior face of the column. The girders were loosely bolted to the column by a single bolt that passed through each of the girder webs and a projected separating bracket that was also cast with the column. As a good amount of tolerance was needed for site erection, the holes were larger than the bolt, leaving the connection with a considerable amount of play. Therefore, Jenney incorporated a clamp consisting of a one-inch diameter wrought iron rod that was bent at one end and placed into a notch cut in the top flange of both girders. At the other end, the clamp was threaded, allowing it to be connected to the column by a nut placed inside the column, thereby pulling the girders tight to the column face, after which the iron column was filled with concrete. The hollow iron columns, filled with concrete, were surrounded with brick that at times was as thick as twelve inches, creating a solid cross section in the building’s exterior piers.

Unlike a true skeleton frame, Jenney did not insert an iron spandrel beam at each floor that should have spanned between the columns that would have connected the column sections into a rigid framework. Instead, to support the windows and masonry spandrels between the piers, Jenney detailed four-inch deep, hollow cast-iron lintel pans, that were also filled with concrete like the columns. Note that these were not one, continuous iron member that spanned the entire distance between the piers but were comprised of two halves that each spanned only the distance between a column’s shelf bracket and the intermediate cast iron mullion. The iron pans were not mechanically connected to either of their iron vertical supports, but simply sat on the concrete filling of the lintel pan below it.

The lack of a mechanical connection between the iron columns and lintel pans was Jenney’s technique to impart some rotational flexibility at the pier/spandrel connection to accommodate expected differential settlement of the piers to minimize cracks forming in the exterior brick, a typical problem in tall buildings sitting on Chicago’s weak soil. At this time, it was still conventional construction practice to make the foundations for both the columns and intermediate mullions the same size, independent of the load they carried. The rotation resulted from the heavier-loaded piers settling at a greater rate than the smaller mullions, transferring more and more load to the mullions, and often resulted in severe cracking in and around them. The easiest way to avoid this differential settlement was to transfer the mullion loads over to the main piers before they reached the ground. If this could be done, not with a single transfer beam at the lowest floor, but with a series of transfer beams as Jenney had detailed, the loads in the mullions would be uniform, and therefore the mullions’ cross-section would not have to increase as the piers did, keeping the windows as large as possible. Jenney, therefore, placed transfer beams to carry the mullions’ loads to the piers at the fourth, sixth, and ninth floors, as well as the roof. These transfer beams also nominally tied the iron columns in the piers together, thereby creating what one might optimistically call a “skeleton frame.” However, if it was Jenney’s intention to create a skeleton frame in the street fronts, these beams should have been introduced at every floor, since the lintel pans were not bolted to the columns and, therefore, any bracing provided by them was negligible at best.