Queen Alia International Airport

Introduction

The new terminal designed by Foster + Partners for the Queen Alia International Airport was inaugurated in March 2013, although its construction was completed in late 2012, with the patronage of His Majesty King Abdullah II of Jordan and Her Majesty Queen Rania Al Abdullah.

Its design follows the practices used for this type of building and establishes a sensible vision adapted to the region and expressed in a specific architecture for an airport. The year of its inauguration received ISO environmental certification, becoming the second airport in the Middle East that gets it.

Location

The new Queen Alia International Airport is located in the area of Zizya at 32km south of the capital Amman Jordan (Arabic: الأردن Al-‘Urdunn) and officially Hashemite Kingdom of Jordan (Arabic: المملكة الأردنية الهاشمية Al -Mamlakah al-Urdunīyah al-Hashimiyah).

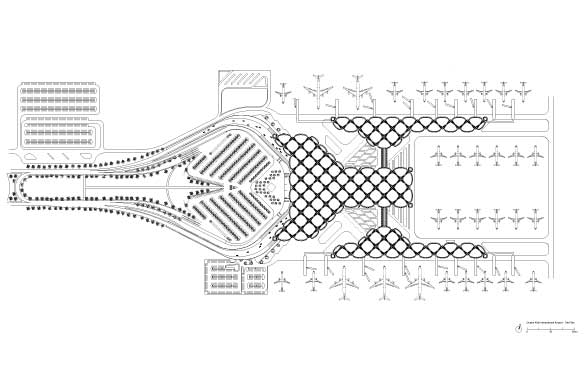

Is the country’s largest airport and the modular design of the terminal will increase year by year its management capacity rating.

Concept

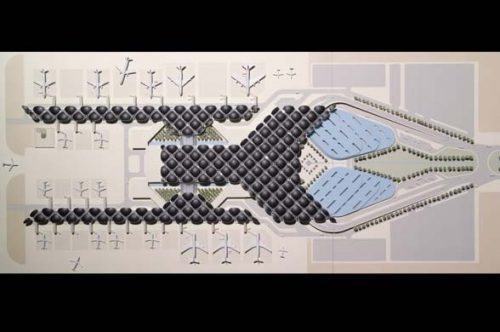

The architects of Foster + Partners were inspired by the Bedouin tents to create a canopy of domes on the new airport terminal.

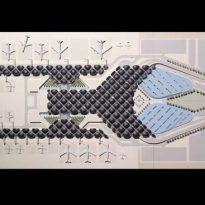

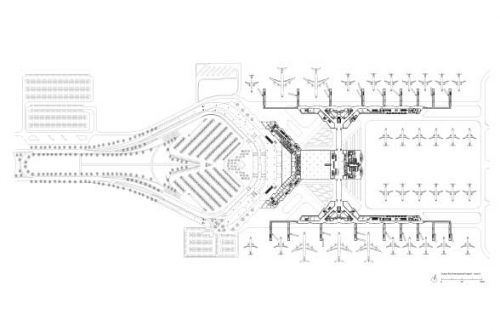

Designed to serve as the main gateway to Amman, one of the oldest cities in the world, its design resonates with a sense of place and local culture. Strategically the building ensures Amman position as the main center of the region of Levante. From a logistical point of view, it allows the airport to grow by 6% annually over the next twenty-five years thereafter increasing the capacity of 3,000,000 to 12,800,000 passengers per year by 2030.

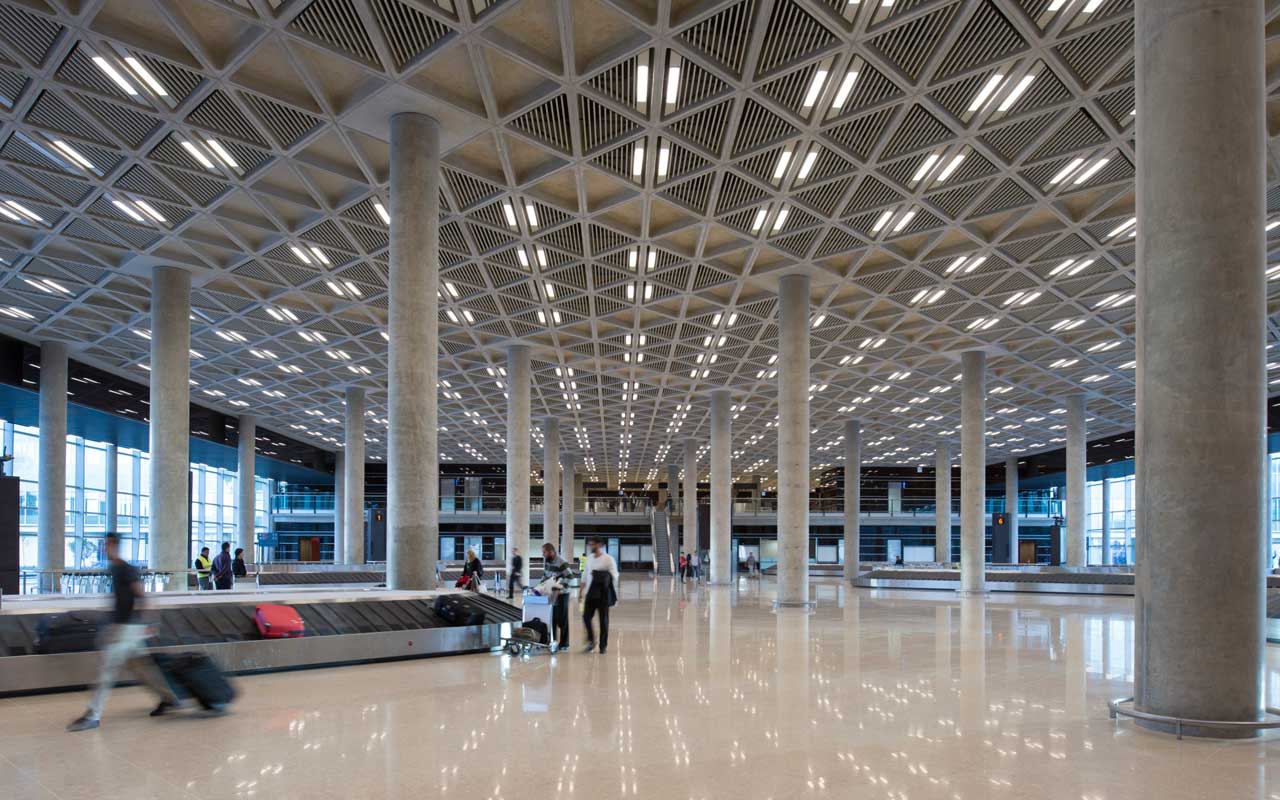

Spaces

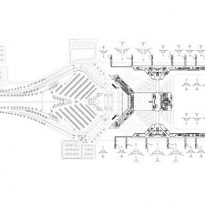

The terminal building is glass on all sides allowing to observe the takeoff and landing of aircraft. On each side of the central building where the main processing areas, shops, lounges and restaurants are located two springs with departure and arrival gates. These volumes are outdoor patios that following the Arabic vernacular architecture contribute to the environmental strategy of the terminal with plants and trees that help eliminate air pollution as prior to its introduction into the treatment system step.

These gardens also refer to the Jordanian tradition of hospitality and celebrate the custom of several families gather in the airport as they are available for family groups, with seats and shade, when they meet to dismiss or receive travelers.

Levels terminal

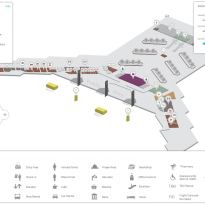

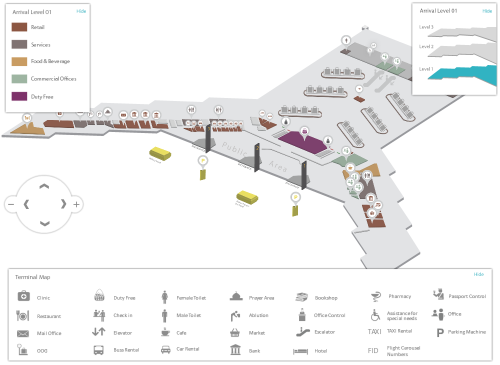

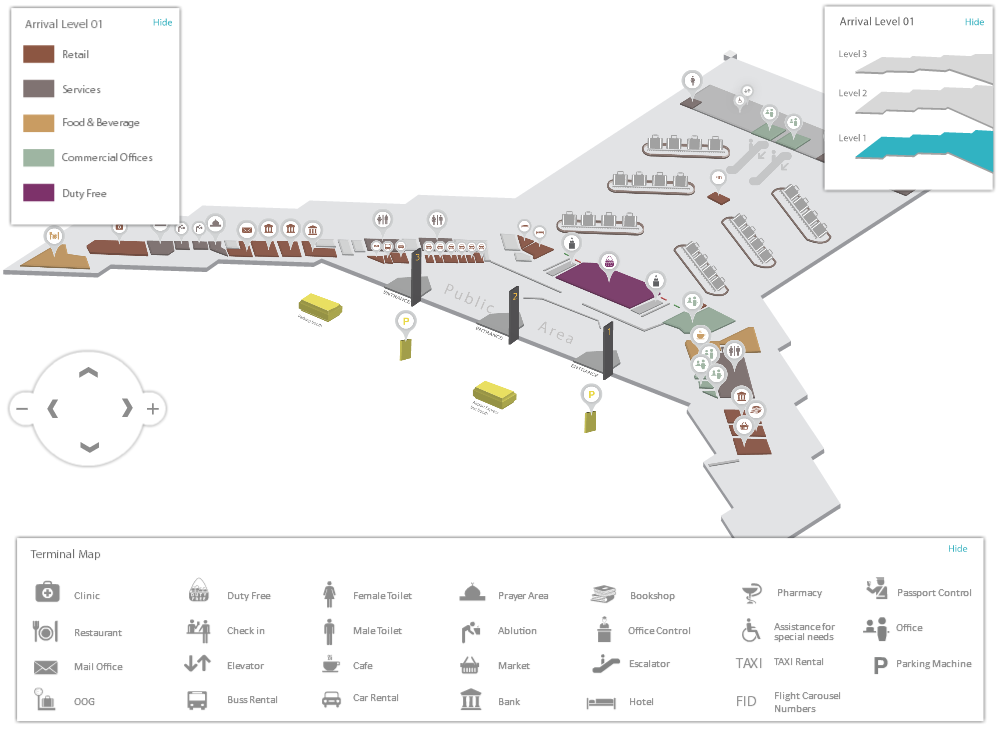

Level 1

Arrivals: houses the arrivals and baggage, with a duty-free shop.

There is also the public area of retail stores, services such as banks, prayer hall and restaurants.

Level 2

Departures: travelers in this area among the passengers Jordanians (doors E) and international passengers are divided. There are not many facilities at this level.

Level 3

Output: in this area passport control is performed, access to exit doors and offers many services. It has the duty free zone, several restaurants and bars, shops, a pharmacy, a playground area and a prayer.

The airport has a third cargo terminal.

Structure and Materials

In response to experience local building and climate of Amman, where summer temperatures vary greatly between day and night the building is constructed entirely of concrete, the high thermal mass of the material provides a passive environmental control.

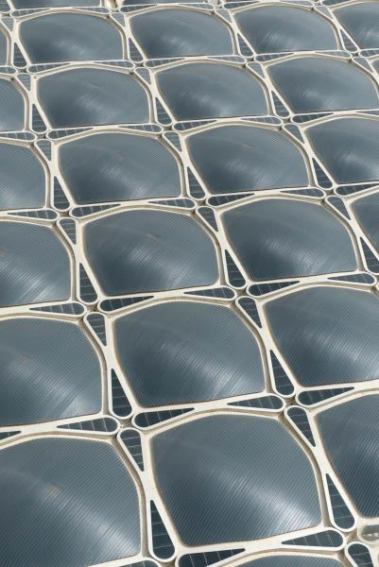

Domes

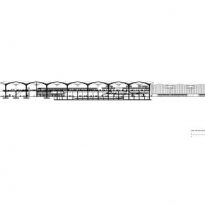

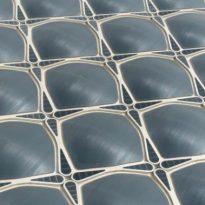

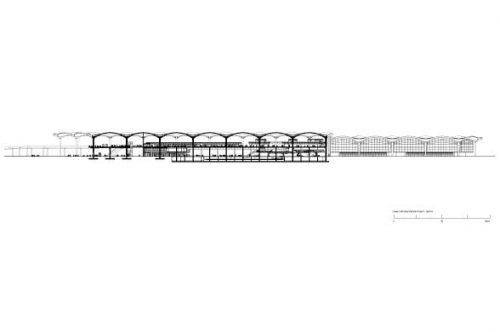

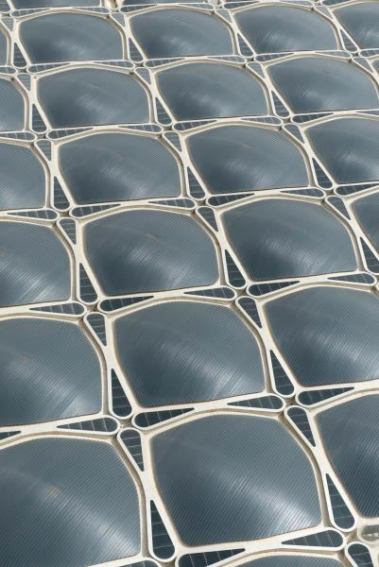

The roof is composed of a series of domes tessellation shallow concrete, which extend throughout the terminal and form eaves to shade the facades.

To allow for future expansion seamless, each dome is a modular unit. The domes branch off from the support columns like the leaves of a palm tree desert and daylight flooded the esplanade through holes forming teardrop-shaped skylights joints between the columns. Traditional Islamic architecture is used throughout the building to generate forms. The bottom of each dome is embossed to resemble the surface of a sheet, while the support grid of concrete columns has split ends designed to resemble the plant stems. Its more than 80 identical domes look like a nod to the ancient desert tents and a light pattern.

Concrete

The cover was done under a roof system precast and poured concrete, which form the sequence of undulating canopies.

team Foster designed the roof bearing in mind the insulating quality of concrete that helps keep the building cool in the day and retains the heat at night, reducing power consumption in an area of extreme weather such as the Amman.

The concrete used was mixed with gravel places to get a similar tone surrounding desert. Besides the thermal advantages of using concrete was presented as the ideal material for the construction of a terminal which highlights the curved shapes. It was used both precast and in situ disposal.

Structural Columns

The structure of the building is supported by reinforced concrete columns robust. The airport has areas 2 and 3 floors on the ground floors of these columns have parallel sides. In the upper floors they shake gently, opening as they rise to the top of the column that is wider and supports the cover.

Circular section, the columns were erected in situ using self-compacting concrete to have a soft, natural finish. To ensure regularity of shape steel forms which minimized the deformation caused by the weight of concrete mounted. Because the roof is constructed from a selection of prefabricated elements, the heads of the columns had to be placed and leveled very precisely so that all the elements fit together properly. This requires a self-leveling mortar and steel plates was used. The heads of the columns were fixed to the body of the same welded steel rings fixed to the underside of the head and welded to the top. These prefabricated heads for columns are 4m wide, 7m high and weighing up to 20 tons, for better malleability were prefabricated hollow like the beams had to endure and then filled with concrete.

Each head of the column has four points which function as brackets which rest on the beams as X or Y, some of 11m.

Video